New platform enables dry tree technology for marginal fields

John Greeves

Versabar Inc.

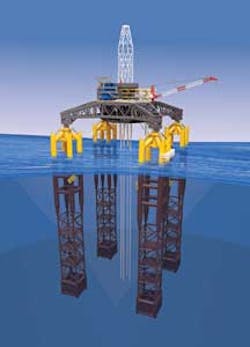

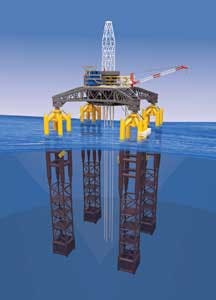

An innovative floating platform technology is now available that represents a new class of deepwater development systems. The new Versabuoy technology responds to wave loading in a fundamentally different way when compared to existing technologies, which results in different performance characteristics. Yet, although the floating platform technology is "new," it is achieved through a unique arrangement of existing components and hardware, all with established performance track records.

For the new platform, the conventional open truss configured topsides is supported by four independent buoys. Each buoy is connected to the topsides by an articulating connection, which decouples the buoy pitch and roll motions from the topsides and from each other. Each buoy is intrinsically stable and has a GM value (metacentric height) typically in the range of 25 to 50 ft (8 to 15 m). Below the water line, the buoys have no connections between them. The taut leg mooring lines and catenary risers attach directly to the deck, facilitating installation, and in-service inspection and maintenance.

There is no element of the system that has not already been deployed in any type of operating system. The most unique component is the articulating connection detail (the "joint") between the buoys and the topside. The joint design has been subjected to more than five years of operating service on the Versabar twin-gantry marine heavy-lift vessels theVB-4,000 and VB-10,000. The design includes a double joint configuration which provides 100% load path redundancy, which facilitates the removal, inspection, and replacement of any component of the wear surface while in-service. The main wear surfaces and support pins within the connections are removed for inspection on an annual basis. The synthetic bushing material used on the key wear surfaces requires no maintenance or lubrication during service, and no replacement has been required.

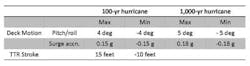

The technology has been developed and refined through multiple engineering studies and scale model test programs. The introduction of the connections between the buoys and topsides results in a multi-body class numerical analysis problem. The individual bodies are able to move independently of each other in one or more degrees of freedom. A key attribute of the system is the low topsides motions experienced even under extreme hurricane storm conditions. Another operating capability of the technology is to rigidly connect together two or more Versabuoy platforms to create larger offshore platforms. This presents the option of a phased development approach where additional platform modules are combined over the life of the development.

Spar platforms

The traditional spar platform population can be broadly split into two segments: those that support full platform drilling operations, and those that support workover rigs and/or full production capacity. The primary operational difference between the two segments is the amount of topsides payload supported by the spar hull.

The system payload of 17,500 tons is at the lower end of the four fully drill-capable spars, but the reduction in fabricated hull steel is significant (17,000 tons of platform hull steel versus 28,000 tons for the equivalent spar). This performance improvement is a direct result of the introduction of the articulated connections between the buoys and topside. The point of applied load on each hull is fixed at this connection point (approximately 50 ft above MSL). This results in much lower solid ballast requirements for the new platform system, and lower hull bending moments. Each hull deploys only 2,000 tons of solid ballast per hull. The platform hull fabrication is divided equally into four identical buoys, each now with a fabricated weight of 4,250 tons. There are many fabrication facilities capable of building structures with a weight of 4,000 to 5,000 tons (typical of mid-sized fixed jacket type structures), compared to those capable of building single piece hulls in the weight range of 20,000 to 40,000 tons.

The lower system displacement requirements combined with multiple smaller hulls also offers simpler construction details. A typical Versabuoy hull arrangement follows a traditional configuration with a hard tank (with variable ballast tanks included) with spatial separation to a lower weighted section to provide the desired GM. The hard tank is now fabricated from rolled tubular pipe sections of a diameter of 19 ft (6 m) or less. This is the largest diameter which can be rolled from a single sheet of steel plate. The hard tank sections are stabilized against hydrostatic collapse through the use of internal ring stiffeners located on 6-ft centers. Also, the ring stiffeners act as inspection galleries. Each hull has a cross sectional spacing between the vertical legs between 40 and 50 ft (12 and 15 m). The majority of fabrication and assembly can be completed at ground level and "rolled up" just like a tradition jacket structure for final assembly.

The new platform design requires the fabrication of less steel, and uses simple fabrication details which result in lower fabrication rates. The increased number of local fabrication facilities that can compete for the fabrication of the hulls adds a further level of cost control through competition.

With the exception of the Kikeh platform offshore Malaysia, historically, spars have required the use of a heavy-lift vessel for the topsides installation. Foundations, hull transport, upending, and mooring line installation and hook-up can be completed using other non heavy-lift assets. Based on current practices, larger platform installations are going to need access to one of the three large international semisubmersible heavy-lift vessels.

As with the Red Hawk spar, the Versabuoy hulls can be transported offshore with the solid ballast already installed. Final upending is achieved through sequential hull flooding. A platform topsides installation is achieved through float-off of the topsides following hull upending and positioning under the deck on a transport barge. Hull ballast control is achieved using compressed air provided from installed equipment on the topsides. Platform installation by local marine contractors is now feasible using locally available assets and resources. Costs will reduce due to both the use of lower cost assets and local competition, and scheduling issues associated with accessing major international assets will be eliminated.

GoM developments

Between 2003 and 2010 upstream commodity prices inflated at a normalized annual rate of approximately 14% per year. Deepwater capable drilling rig day rates have increased from $125,000 to more than $500,000. New Gulf of Mexico requirements for BOPs used for floating platform drilled wells also further serve to limit rig selection and maintain higher prices for Gulf of Mexico deepwater drilling.

In 2012, prices of typical deepwater Gulf of Mexico development options with associated costs (including drilling) are:

The average Gulf of Mexico field has a STOOIP volume (stock tank original oil in place) of 90 MMboe – just about sufficient to support a minimum subsea tieback to an existing platform. Each successful exploration well finds an average reservoir volume of just less than 30 MMboe.

The "old" Gulf of Mexico deepwater fields (Neogene-age reservoirs) exhibit base case ultimate recovery (UR) factors between 30% and 35% of STOOIP. Improved recovery techniques such as water injection, gas lift, or wellbore pumping can improve UR factors to 50% of STOOIP. Additional well side tracks and recompletions can access up to another 10% to 15% through accessing "stranded" reservoir sections.

The "new" deepwater fields (Paleogene-age reservoirs) appear to have URs closer to 10% of STOOIP. Drilling challenges for these "new deepwater" wells are considerable due to drilling to 25,000-plus ft TVD, and drilling through salt and into reservoirs with high-pressures and high-temperatures.

Given successfully drilled and completed wells, improved recovery technology will almost certainly be required to boost production rates and recoverable volumes. Limited development data is available for the costs of "new" Gulf of Mexico deepwater developments, but early indications are that costs are expected to be between 150% and 200% of established deepwater norms.

Dry tree technology

Dry tree development systems provide an excellent development tool for deepwater fields. The systems reduce initial drilling costs, reduce life-of-well costs including side tracks, and reduce the cost to deliver improved recovery solutions. The downside has been the significant increase in development capital required to fabricate and install a floating development capable of supporting drilling, and the deferment of initial production when compared to pre-drilled subsea developments. A technology which supports platform drilled and completed wells at a lower cost than current solutions can therefore could be expected to offer attractive development options for future deepwater developments.

When life-of-well issues, the ability to add improved recovery solutions from a platform with surface completed wells, and the potential for platform redeployment and reuse are considered, the dry tree development option becomes more attractive. Larger subsea developments with multiple drill centers could replace each subsea drill site with a low cost dry tree development. Each dry tree platform could include a reduced amount of full processing and dispense with a central hub platform, or each platform could use limited processing and still tie into a central gathering station. Dry tree solutions remove flow assurance issues and provide options for distributed water injection, gas lift, and wellbore pumping.

Conclusion

Gulf of Mexico deepwater developments continue to cost more due to general commodity pricing pressures and increasing technical challenges, while potentially producing less per well due to lower reservoir productivities. Improved recovery methods will become more important and probably the norm in future deepwater developments.

Platform drilled and completed well developments offer many advantages. Reduced well costs, and improve recovery factors through enhanced recovery technologies such as surface water injection and wellbore pumping. Historically, the capital costs for deepwater capable platforms able to support platform drilling and dry trees have not tipped the general development balance in the favor of this solution except for the largest of fields.

The Versabuoy technology achieves lower costs through system efficiencies due to performance characteristics (less fabrication required), simpler fabrication (lower unit costs), increased local fabrication yard choice (price reduction through competition), and installation using regionally available marine assets. The lower cost platform technology offers operators new development options, which can mitigate development risks and improve economic performance. New technology adoption can only happen when the outcome of utilization is better than the status quo. When that happens, the technology needs to be seriously considered.

The author

John Greeves is the technical director and a shareholder of the Versabar Group of Companies. He holds a Ph.D. in civil/structural engineering and is a UK registered Chartered Engineer. He has worked in the oil and gas industry for more than 20 years including 10 years for Shell International in a variety of positions from design engineer to project manager on projects around the world.