Jeremy Beckman

Editor, Europe

Over the past two summers, a drillship and a semisubmersible rig have been in action off western Greenland for Cairn Energy. More of these vessels will arrive over the next few years as other consortia fulfil their license commitments in this region and other far-north areas such as the Barents Sea, which are opening to exploration and production.

As operators convert discoveries into development projects, demand will arise for harsh-environment rigs capable of year-round operations. One engineering group looking to respond is GustoMSC with its new-concept NanuQ 5000 arctic drillship.

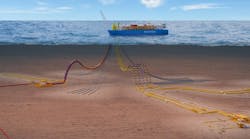

Artist's impression of the NanuQ 5000.

The design is based on the company's experience in developing drillships for varying water depths, and is targeted at operations offshore Alaska, Canada, Greenland, Iceland, Norway, and Russia.

"GustoMSC's drillship track record dates to the early 1970s and ‘80s," said Han Tiebout, manager Product Development, "when five out of 12 Pelican class DP drillships were designed and built with arctic-class hulls. Three of those were destined for the USSR Ministry of Gas – theValentin Shashin, Mikhail Mirchink, and the Viktor Muravlenko. The other two were the Pacnorse and the Canmar Explorer III.

"Over the past decade, GustoMSC has designed two arctic-class drillships for Frontier Drilling (now part of Noble Drilling), namely theBully I and Bully 2. Here the intention is to drill an extended summer season in the arctic, so the hull and marine systems are arctic class, although the drilling systems are not.

"If you look at the capabilities of the NanuQ 5000, which can incorporate either dynamic positioning or turret mooring technology from our sister company SBM Offshore, the design exceeds by far the capabilities of the previously-mentioned vessels and is closer in size to our deepwater P10,000 drillshipsC.R.Luigs, Jack Ryan, Deepwater Champion, MetroStar I, and Metro Star 2. No sacrifices have been made to accommodate the NanuQ5000's winterization features; however, its water depth rating has been tailored to the shallow waters in the arctic."

Mooring options

NanuQ 5000 is 192.3 m (631 ft) long, with a breadth of 38 m (124 ft), a depth at centerline of 18.3 m (60 ft), and a drillfloor height (above keel level) of 39.7 m (130 ft). In the turret-moored version, the turret is positioned forward of midship to improve ice- and weathervaning.

An internal turret with an ID of 12.4 m (40.7 ft) is fixed to the sea floor via a 12-point mooring system. In this case, power is supplied by six 4-6 MW diesel generator sets, with two 10 MW Azipod VI series thrusters aft and two 2.5 MW tunnel thrusters forward. These allow disconnection and connection of the moorings, and provide redundancy for safe return to port or extended life support under emergency conditions. Four azimuthing retractable thrusters are included for the fully DP-3 Class version of the NanuQ. Azipod technology has been proven in arctic class tankers and icebreakers.

"Turret-moored drillships have been used since the 1970s offshore Canada," Tiebout said. "The turret design is derived from SBM's long turret mooring experience, which includes designs for floating platforms in arctic waters, i.e. Shtokman and White Rose. The turret-mooring application is designed to work year round, with ice management." When ice conditions exceed the design limits, he explained, it would be possible to quickly disconnect the mooring system.

The hull form has been extensively tested in ice laboratories, Tiebout added, and the hull strength complies with the latest Polar Class requirements. "Rules and regulations of Classification Societies such as ABS, DNV, and Russian Register have been taken into account in the design of the NanuQ 5000," he pointed out. "Results of ice model testing have been used to verify station keeping and free sailing calculations."

Autonomous operations

The NanuQ 5000's drilling capabilities are suited to conventional needs, with a subsea BOP in 5,000 ft (1,524 m) water depth and a single-activity derrick, although there are options in the design for operations with a surface BOP and seabed shut-off device. All risers and tubulars are inside the hull or superstructure enclosures aft of the derrick. Mud and bulk storage tanks are inside the hull aft of the (turret) moonpool. All other drilling facilities are arranged around the derrick and drillfloor, with the BOP storage forward between the drillfloor and 180-persons accommodation block.

The vessel is designed to provide autonomous drilling operations in arctic conditions for up to 120 days. "That includes taking on board all drilling consumables for up to two wells," Tiebout noted.

Tank capacities range from 8,500 cu m (300,175 cu ft) for fuel oil to 1,400 cu m (49,440 cu ft) for potable water; 1,700 cu m (60,035 cu ft) for active mud and 2,500 cu m (88,286 cu ft) for reserve mud; and 1,200 cu m (42,377 cu ft) for cuttings storage. The aft deck logistics and bunker stations are protected by windwalls – providing fully enclosed working areas – for re-supply over the stern during winter ice conditions. "During the open-water season, supplies are conveyed to and from the drillship via port- and starboard-side bunker stations with the supply vessel alongside," said Tiebout.

Arctic conditions necessitate inclusion of some equipment that might not be required on a conventional drillship working in the Atlantic or off northern Europe, especially in view of the remoteness of the drilling operations. "One needs to be able to store more back-up equipment and systems to keep operational uptime at acceptable levels," Tiebout explained. "In addition, the HVAC and ice removal systems are substantially larger than on conventional drilling rigs."

The winterization features have also led to lay-out changes to include specialized handling systems, and rearrangement of the normal positions for the moonpool and storage areas.

Tiebout said the recent summer campaigns off Greenland would have benefited from these capabilities.

"Working offshore Greenland basically means the requirement to have reliable iceberg observations and tracking systems," he said. "The fully winterized NanuQ provides the advantage of being able to continue drilling during ice spray and heavy snowfall conditions, which also occur during Greenland's summer season. And the inherent large onboard storage facilities make re-supply of materials less of an issue."

However, no two arctic areas are alike – each is different in its characteristics. One of the most severe areas is the Beaufort Sea, although large icebergs do not occur here. Offshore Labrador, the ice conditions are less severe but there can be numerous icebergs at certain times of the year.

"Our design philosophy," Tiebout explained, "is that the drillship operates in all areas in an ice-managed environment, but can survive on its own should the ice management systems fail to operate as intended. In general, we are catering for ice thicknesses of up to 4 m [13 ft], a wind speed of up to 100 knots and design temperatures of -35 to -40°C [-31 to -40°F]. The environmental conditions directly influence the drillship's operational uptime."

Maximum water depth range for the NanuQ is 1,500 m (5,000 ft). But Tiebout notes that the real challenge in the arctic is shallow water, due to the allowable vessel offset when drilling.

Regulatory issues

According to Tiebout, the main regulations impacting design of arctic drilling vessels are ISO 19906, the mandatory polar codes, and the new regulations emerging post-Macondo.

"Operating requirements for offshore drilling vary widely among the Arctic nations," Tiebout noted. "However, there has been an initiative between Russia and Norway to harmonize their regulatory systems [Barents 2020]. Greenland is adopting the Norwegian standards. Canada has implemented a ban on arctic drilling until a public hearing by the NEB provides input for new permitting standards. The US BOEMRE is setting up new acceptance standards; and the Environmental Protection Agency is also involved with respect to emissions."

For retrieval of subsea BOP systems during ice build-up, the procedure would be "not much different from open-water drilling," he claimed. "That means leaving the equipment on the seabed if the time to abandon is too short; or, if time allows, retrieving the riser and the BOP stack. Much depends on the quality of the ice prediction and ice monitoring systems. With the NanuQ 5000, the location of the moonpool means it is protected by the ship's hull, which allows for retrieval of the BOP in ice conditions."

GustoMSC said that the latest technologies in emission reduction are employed in NanuQ 5000's power generation and distribution systems.

"In addition, NOx and SOx reduction and particle filter systems are installed," Tiebout added. The drilling systems are designed for zero discharge. As for water treatment and handling of drill cuttings, "that is a logistical issue which needs to be resolved jointly by the operator and drilling contractor. Each arctic area is different in that respect. However, our drillship will provide onboard storage facilities for drilling waste."

Tiebout says that GustoMSC has had serious discussions with a variety of operators and contractors about its concept. "Taking into account the current backlog among shipyards worldwide, it would be prudent to assume that the first NanuQ drillship could enter service in the 2015 timeframe," he said.

Tiebout also noted that GustoMSC is working on an "arctic version of a harsh-environment jackup," since the company anticipates that a substantial amount of offshore drilling in the arctic will be in very shallow water. "To allow work in ice conditions, we are focusing on a jackup design with tubular legs," he explained. "An example of such a rig (although not currently tailored for arctic conditions) is Swift Drilling'sSwift 10. We have discussed our arctic jackup design with various parties and ice model testing has already been conducted in an ice testing laboratory."

Offshore Articles Archives

View Oil and Gas Articles on PennEnergy.com