Perdido advances deepwater GoM production possibilities

Project features first spar wet tree direct vertical access wells in waters more than a mile deep

Bruce Beaubouef

Managing Editor

Located in an isolated, ultra-deep sector of the Gulf of Mexico (GoM), Shell’s Perdido is the world’s deepest offshore oil drilling and production platform. Moored in 2,450 m (8,000 ft) of water in Alaminos Canyon block 857, the Perdido development opens up a new frontier in deepwater oil and gas production, and represents a number of firsts in the offshore oil and gas industry. These include:

- First commercial production from the Lower Tertiary reservoir in the Gulf of Mexico

- First full host subsea separation and boosting in the Gulf of Mexico, removing about 2,000 psi of backpressure from the wells

- First spar wet tree direct vertical access (DVA) wells in water more than 2 km (1.2 mi) deep.

Perdido is also the world’s deepest direct vertical access spar, and the facility acts as a hub for and enables development of three fields – Great White, Tobago, and Silvertip. It gathers, processes, and exports production within a 48-km (30-mi) radius. Tobago, in roughly 2,925 m (9,596 ft) of water, will be the world’s deepest subsea completion. The project is operated by Shell Oil Co., which owns 35%; with Chevron (37.5%) and BP (27.5%) owning the remaining interest.

Production from the Perdido development began in March, and is expected to ramp up to annual peak production of more than 100,000 boe/d.

Strategic development

When Shell acquired the ultra-deepwater leases for Perdido in 1996, the technology to develop them did not exist. A large tension leg platform – common on other deepwater developments – would not work at Perdido because of the extreme water depths. Whatever floats on the surface has to support the weight of everything below. In Perdido’s case, just the weight of the mooring lines, risers, and other equipment hanging from the platform would be overwhelming.

Engineers also had to design for the higher crushing pressures of depths greater than 9,000 ft, and other environmental forces such as storm-driven waves, hurricane-force winds, and the Gulf of Mexico’s strong loop currents.

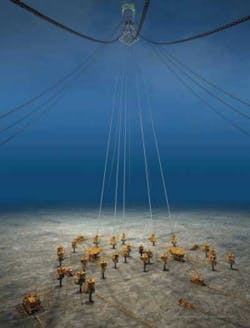

There are as many as 35 wells in the Perdido development plan. Twenty-two are directly under the spar. A conventional deepwater production system would require 22 risers with all their associated bulk and weight. Another 13 will be offset wells with tiebacks to the host platform.

The subsea system

Two related technologies make the subsea portion of the Perdido project viable: the subsea boosting system, and a surface blowout preventer for drilling and completing the direct vertical access subsea wells.

Hardware on the seabed

The core of Perdido’s subsea boosting system (SBS) is a cluster of five vertical gas-liquid cylindrical cyclonic (GLCC) separators. The body of each separator is a heavy pipe, 35-in. (89-cm) diameter and 350 ft (107 m) long. Production from all of the wells comingles in these vessels. The primary function of the caissons is to provide a surge volume for the separated production liquids. The passive system relies on centrifugal force to separate gas and liquids as they swirl down the outer walls of the caisson.

All but the uppermost portion of the separator is inserted into the seabed. A 1,600-hp electric submersible pump (ESP) is deployed inside, near the bottom of the vertical caisson.

At the top of the separator, just above the mud line, sits a two-story tall inlet assembly. Above that, a 17-ft-long (5-m-long) reducer brings the diameter of the pipe down to 14 in.(35.5 cm), matching the diameter of the riser. From there, the riser extends some 7,800 ft (2,377 m) to the Perdido spar.

Each caisson’s inlet assembly connects to the host through a top-tensioned riser that contains three separate flow paths. The outer annulus of the riser carries the relatively dry gas. The middle annulus carries produced liquids, which are pushed to the surface by the power of the ESP at the bottom of the separator caisson, and a small diameter pipe in the center carries liquid sent down from the surface to prime and cool the submersible pump. The 14-in. riser allows direct vertical access to the boosting pump at the bottom of the caisson.

Subsea trees and manifolds

The new standard tree system developed for Perdido incorporates Shell’s experience with previous deepwater installations as well as some recent innovations. The new system is rated for 10,000 psi and 10,000-ft water depths. It has a retrievable flow module that contains both a multiphase flow meter and a choke. The tree’s modular design allows it to be configured for the requirements of the field, and its compact, lightweight components make it easier to service and deploy than previous systems.

All of Perdido’s wells are being drilled either from the spar itself, or from moored or dynamically positioned floaters with single or dual derrick systems. That difference in drilling systems led to some variety in the way the subsea trees were installed.

The idea of using wet-tree wells with direct vertical access from the spar helped minimize the size of the host platform. All of the drilling, completion and subsequent maintenance of the spar’s 22 wells can be completed using the onboard rig. The rig is held in a fixed position over a well by adjusting the mooring lines on the spar. Tension on the mooring lines can be adjusted to reposition the rig over a different slot. This system is significantly less expensive than using a fifth-generation floating rig to complete and service the wells.

FMC Technologies supplied the subsea completion and subsea processing systems. The scope of supply included 17 subsea trees rated for 10,000 psi; two subsea manifolds; five subsea caisson separation and boosting systems; topside and subsea controls; and related subsea equipment.

Spar production platform

Shell has more than 30 years of success in the design, fabrication, installation, and operation of the world’s most advanced deepwater systems. Perdido is Shell’s first spar host drilling and production platform – a system selected because of the extreme water depths, the nature of the reservoirs and remoteness of the field.

Technip was announced as the spar and mooring contractor in April 2006 and began working on a detailed design in June. An engineering, procurement, and construction contract was awarded to Technip USA in November 2006 for the design, fabrication, and dry transport of the spar and mooring system for the Perdido development.

Perdido is Shell’s first spar host drilling and production platform – a system selected because of the extreme water depths, the nature of the reservoirs, and remoteness of the field.

Heerema Marine Contractors was named in the spring of 2006 as the primary transportation and installation contractor. It was a critical step because the finished spar and topsides would have to be designed to fit the capacities of the available transport and installation vessels. To complete Perdido, Shell needed two of the largest installation vessels in the world: Hereema’sBalder for the spar and Thialf for lifting and setting the single-lift topsides.

Perdido’s spar includes a cylindrical upper section (the hard tank), a trussed midsection of tubular legs and braces, and an enclosed octagonal bottom section (soft tank) to contain the fixed ballast. The outer diameter of the hard tank is 118 ft (36 m), which was small enough to allow offshore installation of the topsides by theThialf, yet large enough to provide the required buoyancy and to contain the platform’s various liquid storage tanks. The spar is 555 ft (169 m) tall, with a draft of 505 ft (154 m) and gross weight of 20,000 tons (18,143 m tons). Strakes around the circumference of the hard tank are standard equipment on deepwater spars. Strakes help keep the platform from oscillating by disrupting the flow of ocean currents around the spar.

Mooring system

All of Shell’s previous deepwater mooring systems have used steel mooring lines; Perdido is the first to use mooring lines that are primarily polyester. Perdido’s mooring system consists of nine anchor lines that average more than 2 mi in length. The nine taut lines are oriented in a 3x3 pattern, and are anchored to the seabed by 18-ft diameter suction piles that range from 87 to 103 ft (26.5 to 31 m) in length.

Hereema’s SSCVBalder entered the Perdido field on June 20, 2008, to install the first cluster of suction piles. Each pile was individually upended, lifted overboard and lowered to the seafloor, where it was oriented correctly before being allowed to penetrate the seabed under its own weight a few feet into the mud. A remotely-operated underwater vehicle (ROV) was used to close the water relief valves at the top of the pile, then to apply suction until the pile reached its target penetration. The water depth of the mooring piles ranged from about 7,600 to 8,600 ft (2,2316 to 2621 m). The installation of pile P6 at 8,631 ft (2,631 m) set a new world record for the deepest permanent mooring pile.

Since polyester rope is more difficult to handle in a winch, the ends of each mooring line are fitted with lengths of chain. On the seabed, ground chains and mooring shackles connect the polyester mooring lines to the suction piles. At the surface, dedicated chain jacks on the platform control tension on the lines. Perdido employs an “active” mooring system, which means that the mooring lines can be pulled in or let out to reposition the spar over drilling locations on the seabed, reaching any point within an area roughly 350 ft in diameter.

Perdido fast facts

- One day’s production from Perdido is equivalent to the energy needed to fuel 500 cars for 15 years

- First commercial production from the Lower Tertiary reservoir in the Gulf of Mexico

- First full host subsea separation and boosting in the Gulf of Mexico, removing about 2,000 psi of backpressure from the wells

- First spar wet tree direct vertical access (DVA) wells in water more than two kilometers (1.2 mi) deep

- The project achieved 10-million hours without a lost time injury

- Located 320 km (200 mi) from the Texas coast in Alaminos Canyon block 857

- The Great White field represents about 80% of Perdido’s total estimated production

- Perdido’s project life is expected to be about 20 years

- Construction of the Perdido host spar began in late 2006

- Topsides were mated with the spar in a single lift in early 2009.

Offshore Articles Archives

View Oil and Gas Articles on PennEnergy.com