Duane DeGeer

INTECSEA

Editor’s note: This is the second in a series about the unique challenges encountered when attempting to design, engineer, install, and operate offshore oil and gas facilities in the Arctic. The next installment will be on engineering arctic topsides facilities.

Production pipelines and flowlines in the North American Arctic have begun to move offshore in the past decade, as engineering companies draw upon a trove of environmental, geotechnical, and operational data accumulated during the past 30-plus years. During this time, engineers have been able to develop new design processes, introduce pioneering construction methods, and develop first-in-class subsea solutions to deal with the extreme loading conditions posed by the region’s ice and sub-freezing temperatures.

Arctic pipeline design proficiency has progressed steadily since the spike in oil prices brought on by the 1973 Arab Oil Embargo and, coupled with discovery of giant Prudhoe Bay field on Alaska’s North Slope, provided the economic and strategic impetus to design and construct the first large-scale arctic pipeline project, the Trans Alaska Pipeline System (TAPS), commissioned in 1977. TAPS engineers developed many practical solutions to a range of technical, logistical, and environmental challenges stemming mainly from permafrost thaw potential and low environmental temperatures in the difficult, isolated terrain.

Still in operation, TAPS has provided experience in operating long-distance (800 mi/1,287 km), large-diameter (48 in./122 cm) transmission lines in the unique arctic environment, and has allowed other proposed gas transmission lines, such as the Mackenzie Gas Pipeline and trans-Alaska gas pipeline, to proceed with a higher level of design, construction, and operational confidence. Tempering these technical and strategic successes, however, is the realization that the huge financial investment required – to conduct initial feasibility studies and front-end engineering to determine the viability of a proposed arctic development; to design and install facilities that can recover resources from remote arctic locations; and to transport production to distant markets – means that only the very largest, high-volume discoveries are destined to be developed.

The Arctic remains among the high-cost production areas in the world because the unique environment magnifies the complex problems that must be analyzed and solved when planning a grass roots field development in the region. Not only is inordinate advanced planning required; the designs of facilities, installation strategies and methods, and maintenance and operating programs must be developed on essentially a project-by-project basis. Yet, the growing body of knowledge about arctic conditions coupled with improvements in material behavior, advances in analytical techniques, wider acceptance of a strain-based design philosophy, and, finally, implementation of a reliability-based approach to the operation of arctic pipeline systems, enable some of these offshore prospects to be developed.

The first subsea arctic oil production pipeline in the North American Arctic was installed in 2000 by BP in about 37 ft (11 m) of water to connect Northstar production facilities on Seal Island, about 6 mi (9.7 km) offshore Alaska in the Beaufort Sea. Twin specially designed, 10-in. (25 ½-cm) diameter steel pipelines comprise the heart of the Northstar system, which was buried 7-to-10 ft below the sea floor to avoid ice scour and is equipped with three leak-detection systems. Northstar crude is transported overland to TAPS through an elevated pipeline.

The second subsea arctic production pipeline to be installed is at the Oooguruk field, about 6 mi offshore Alaska in the Beaufort Sea near the Colville River delta. Installed in the winter of early 2007, the Oooguruk flowline system consists of a three-phase, 12-in. x 16-in. (30 ½- x 41-cm) pipe-in-pipe (PIP) production flowline bundled with an 8-in. (20-cm) water-injection line, 6-in. (15-cm) gas lift/injection line, 2-in. (5-cm) diesel fuel line, and power and communications cables. The location of the Oooguruk flowline system, in less than seven feet of water at the mouth of the eastern distributary of the largest river drainage system on the Alaskan North Slope, presented unique loading conditions and thermal interactions, imposing additional design requirements to integrate with solutions for more conventional arctic conditions. The Oooguruk production flowline represents the first application of PIP flowline technology offshore Alaska.

More recently, the Nikaitchuq flowline bundle was installed and is scheduled to begin operation in early 2011.

Offshore arctic challenges

Aside from standard operating pressure containment, the primary loading conditions to be considered in the design and construction of offshore arctic pipeline and subsea systems include ice gouging or scour, upheaval buckling, permafrost thaw settlement and/or frost heave, and strudel scour.

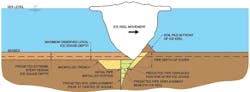

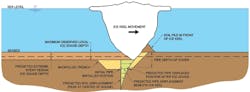

Ice gouging or scour is the most significant and most unpredictable environmental loading condition influencing arctic offshore pipeline design. The accepted solution to protect a subsea pipeline from this threat is to bury the line deeper than the maximum gouge depth expected over the design life of the pipeline. For pipeline systems, research into safe burial depth finds that soil below the scouring keel of the ice will deform, imposing high shear and bending loads on the buried line. More recently, research to reduce overall uncertainty associated with ice keel interactions with the seabed has been directed towards understanding ice keel gouging and integrating these data with historical seabed mapping data. Upheaval buckling potential, caused by differences between installation and operating temperatures, also can be influenced by careful selection of burial depth. Subsea systems must also be protected from the extremely high ice loads. Off the east coast of Canada, glory holes are excavated on the sea floor so drill centers and subsea equipment can sit below the seabed elevation, thereby offering protection from ice impact.

Permafrost thaw settlement and frost heave can impose long-term displacement-controlled bending on a subsea pipeline, and can contribute to a pipeline being strained outside the elastic limit into the plastic region of the material deformation; thus the need for strain-based design. These unique arctic loads can be present along a buried subsea pipeline route, especially near shore where shallow permafrost is likely to exist; and also onshore, where a buried line may traverse continuous or discontinuous permafrost.

Strudel scour can occur in early spring if seasonal river outflows precede the thawing of winter sea ice, with the result that water flows on top of the sea ice. If river water atop sea ice flows into depressions or cracks in the ice, it can penetrate the ice cover and initiate a powerful downward jet of water that can erode the sea floor. Erosion by this strudel scouring may expose long sections of a buried subsea pipeline.

Burial depths sufficient to guard against ice gouging might be adequate protection from strudel scour, and some designers consider the probability of strudel scour at the location of a subsea pipeline to be quite low. However, if heat escapes during operation of a subsea flowline in shallow water and warms the sea water above the line, that fugitive heat dissipation might prevent the ice above the line from becoming as thick during winter. In the spring, such artificially thin ice could be susceptible to early cracking and, in turn, strudel scour.

Pipelines, flowlines, and subsea systems must operate within an acceptable thermal regime, and provide the necessary containment and monitoring to ensure acceptable levels of risk. For example, visual monitoring is not always a reliable way to detect strudel scours or pipeline exposure locations, and the pipeline itself must not exceed certain allowable strains. Using PIP flowlines on both the Oooguruk and Nikaitchuq bundles allows for double containment and an annulus in which insulation (vacuum or other) can be used. In addition, a thermal monitoring system can detect operational thermal changes as well as thermal changes from pipe exposed to cooler seawater, possibly signaling an issue with upheaval buckling or strudel scour. In these cases, analysis and design of the flowline system must consider these design/operation aspects in an integrated manner.

Looking ahead

As our understanding of the unique loading conditions of the arctic develops, as subsea equipment reliability and performance advances, and as our computational expertise in flow assurance and system operability improves, other arctic development concepts are becoming possible. Subsea tiebacks now exceed 100 km (62 mi) in length, offering possible arctic subsea completions without a permanent host structure. All-electric subsea technology, full subsea separation and water re-injection, seafloor chemical storage and injection, and gas re-injection technical advancements have made possible the concept of full subsea completions in the Arctic. Depending on reservoir conditions, some development options are at a high technology readiness level, some even field-proven in non-arctic regions.

Advancements in trenching and dredging methods and equipment make it possible to consider fast, efficient pipeline trenching operations and glory hole excavations in as much as 150 m (492 ft) water depth. Development of cost-effective mechanical protection of subsea equipment also progresses, providing an economical compromise between glory hole dredging and structural resistance to iceberg scour.

Arctic offshore pipeline design, subsea equipment technology, subsea system operating practices, and understanding of arctic environmental conditions continues to advance and, as a result, the options available for Arctic and cold regions field development grow. Ice and metocean conditions, seabed bathymetry, soil conditions, presence of permafrost, reservoir conditions and layout, and development location all play important roles in selecting an arctic production facility. These factors must be considered integrally, and the design philosophy must provide the framework necessary to consider all aspects of Arctic development in one overall life-cycle design system. This, in turn, will optimize levels of risk and ensure consistent personnel and environmental safety over the lifetime of an Arctic field development.

References

1. Paulin, Michael J., Nixon, Derrick, Lanan, Glenn A., and McShane, Brian, “Environmental Loadings & Geotechnical Considerations for the Northstar Offshore Pipelines,” August 2001, Proceedings of the 16th International Conference on Port and Ocean Engineering under Arctic Conditions.

2. Lanan, Glenn A., Cowin, Todd G., Hazen, Beez, Maguire, David H., Hall, J.D., and Perry, Conrad, “Oooguruk Offshore Arctic Flowline Design and Construction,” (OTC 19353), May 2008, Offshore Technology Conference.

3. INTECSEA Quarterly Journal, 2nd Q., 2010

About the author

Offshore Articles Archives

View Oil and Gas Articles on PennEnergy.com