Marathon joins ranks of Norwegian production operators

Nick Terdre, Contributing Editor

Marathon took its production capability to a new level in June when the Alvheim field came onstream in the Norwegian North Sea. When plateau output is reached towards year-end, Alvheim will be producing close to 120,000 b/d of oil.

With a 65% stake in the field, Marathon’s net share will be around 80,000 b/d, raising its global production by around 20% – so this is clearly an important project for the company, says managing director, Kristin Færøvik. Its partners are ConocoPhillips with 20% and Lundin with 15%.

Alvheim resulted from an intensification of the company’s activities in Norway around the turn of this century. It already had a long presence in the sector, notably as a partner in the Heimdal field where it has a 23.8% interest. But in 2001 it was approved to act as an operator.

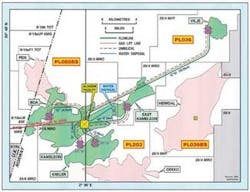

Heimdal lies about 100 km (62 mi) north-northeast of Marathon’s Brae cluster of fields in the UK sector. Having developed a good knowledge of the geology of the Brae-Heimdal corridor, and having identified some interesting leads in the Heimdal area, the company drilled a series of successful wells in 2003 and 2004. These led to the confirmation of commercial reserves in the three fields that comprise Alvheim – Kneler and Boa, both discovered by Marathon, and Kameleon, discovered by Norsk Hydro. Alvheim lies mainly in block 24/6 and 25/4, between Heimdal and the UK median line.

High oil volumes

The company moved quickly to draw up and submit plan of development and operation (PDO), with government approval coming in October 2004. It was also a partner, with 46.9%, in Hydro’s Vilje find 19 km (11.8 mi) to the northeast. The Alvheim and Vilje licensees agreed to develop Vilje as a subsea tieback to Alvheim. That PDO was approved in March 2005.

Reserves at Alvheim and Vilje are around 250 MMboe, according to Marathon. The Norwegian Petroleum Directorate gives figures of 154 MMbbl of oil and 5.7 bcm (201 bcf) of gas for Alvheim and 52 MMbbl for Vilje. The surprise for the partners was that the reserves were predominantly oil, as the Heimdal area until then had yielded primarily gas.

The volume of reserves justified a stand-alone production facility, and the fact that the fields stretched over a wide area, some 16 km (10 mi) from east to west, led to the decision to deploy an FPSO. The concept was relatively new to the company, apart from a benign-environment unit it had operated off Gabon. For the North Sea, however, a harsh environment vessel was required with an internal turret. The hull procured for the vessel came from theOdin multi-purpose shuttle tanker.

FPSO Alvheim has a production capacity of 120,000 b/d of oil and 125 MMcf/d of gas, and injection capacity of 180,000 b/d of produced water. Maersk Contractors, which supported the project team with the FPSO conversion during the development phase, has been contracted also to operate the ship, owing to its involvement with FPSO projects around the world, says Alvheim asset manager, Geir Solli.

Multi-lateral milestone

Development drilling is divided into two phases. The first, still in progress, comprises 12 wells, 10 producers, and two water disposal wells. Drilling is being performed by the Odfjell semisubmersible,Deepsea Bergen, which came on contract in May 2006, about 10 months later than originally expected.

The wells are clustered around subsea manifolds at four drilling centers, one on Boa, two on Kneler, and one on east Kameleon. At start-up, five wells had been completed and tied back to the FPSO, and another three were due to be tied back in July. The last two wells are being drilled now, andDeepsea Bergen is expected to conclude the first drilling phase in January 2009.

Several of the wells are set to be multi-laterals, the first Marathon has drilled in the North Sea. One, a tri-lateral, will be drilled on Kameleon. The second drilling phase is scheduled for 2010, when three more wells are to be drilled by the Songa semisub,Songa Dee. Two of these will be at the drilling center on east Kameleon, where no wells have yet started.

Drilling to date has gone to plan, and the wells in place have fulfilled expectations, says Solli. The reservoirs are all fairly shallow, with normal pressures and temperatures. The least complicated is Kneler, which consists of an unsaturated oil column. Kameleon and Boa both have fairly thin oil columns with gas caps. Placement of the wells in these reservoirs, which have horizontal sections of 1,200-1,500 m (3,397-4,921 ft), was a challenge, but has proceeded smoothly, says Solli.

There is also an underlying aquifer, so there is no need for water injection. But water management will be an important issue, and water breakthrough in the wells is expected relatively soon. Gas lift is applied in the production wells.

The four drilling centers lie between 2.6 and 5.6 km (1.6 and 3.48 mi) from the FPSO, each connected to the vessel by a 10-in. (25.4-cm) production flowline, a 4-in. (10-cm) lift-gas line, and an umbilical.

Cross-border extension

Boa extends across the median line into the UK sector, as Kerr-McGee, the then operator on the UK side, confirmed with an exploration well in 2004. Norway’s oil and energy ministry promptly came to an agreement with the UK authorities that this small extension, which holds only about 1% of the overall reserves, should be regulated by Norway. For their part, the Alvheim partners reached agreement with Maersk Oil, the current operator on the UK side, and approval for the UK part of the development was given in May this year.

Subsea construction, pipelay, and tie-ins were by Technip Offshore, and subsea trees and associated equipment were supplied by Aker Kvaerner Subsea.

Oil is offloaded into shuttle tankers under a contract with Teekay Shipping, while gas is exported by a 38-km (23.6-mi), 14-in. (35.6-cm) pipeline across the median line to a connection into the UK Sage pipeline.

Vilje, which is tied back to the ship by a 19-km (11.8-mi), 12-in. (30.5-cm) production line, and a 4-in. (10-cm) lift-gas line and umbilical, will be brought onstream shortly, when the allocation metering system has been commissioned. The two wells were drilled and completed by Dolphin semisubBideford Dolphin and Odfjell semi Deepsea Delta.

Phase two plan

A second phase of Alvheim development is already in the works. This involves the subsea tieback of Volund, which lies south of the other fields in 24/9. It was discovered by Marathon in 2004, after the company already was under way with development planning for Alvheim. Volund, which contains an estimated 41 MMbbl, was approved for development in January 2007 and is expected to come onstream in the second half of 2009.

It will be developed with three producer wells and one water injector tied into a manifold. The manifold will be connected to the FPSO by an 8-km (5-mi), 12-in. (30.5-cm) production pipeline, a 14-in. (35.6-cm) water line, and a 4-in. (10-cm) lift-gas line. Two of the wells will be drilled byDeepsea Bergen, which will remain on contract with Marathon until around mid 2009. Drilling and completions will then be taken over by Songa Dee.

There is further prospectivity around the Alvheim fields which Marathon intends to test. In mid-2009 it plans to use theBredford Dolphin to drill the Marihøne prospect on another part of 24/9. Further drilling around Alvheim will be carried out by the Transocean semi Transocean Winner, which has been jointly contracted by Marathon, Lundin, and Talisman starting in late 2009.

Although Alvheim came onstream more than a year late, Færøvik says the project has gone very well. “We set a very aggressive time-line up front, and in fact the time from PDO submission to first oil was less than four years,” she points out.

Since sanction capex has risen from NKr 9.2 billion to NKr 16.9 billion ($1.8 billion to $3.3 billion), including the second-phase wells, but at the same time the economic environment has also changed dramatically. “At sanction the project was marginal – we were taking some risk,” she says. “Now it’s an extremely robust project economically.”

The discovery of Alvheim and Marathon’s rapid move into development were hailed at the time as the first fruits of the government’s new policy of inviting smaller companies to operate on the NCS. Moreover, it provided tangible proof that there were still significant volumes to be found. Alvheim, as Solli points out, is the first field to be developed since the early days by a company which is neither Norwegian nor a major.

Conversion issues

The project delays arose because it proved more challenging than expected. Though the multipurpose shuttle tanker concept was intended to facilitate conversion to production ship mode, the process of turningOdin into an FPSO was not straightforward, Solli says. The vessel came equipped with a DP-3 system with four thrusters and plenty of built-in redundancy. A lot of work was required to make changes to the systems for operations in FPSO mode.

The vessel was delivered from Keppel FELS in Singapore, where the hull conversion took place, to the Vetco Aibel (now Aibel) yard at Haugesund in western Norway with a substantial amount of outstanding work still to be done on the hull. The yard, which had originally been contracted for topsides assembly including the fabrication of some 9,000 metric tons (9,921 tons) of pre-assembled units, then had its scope of work expanded.

The vessel arrived in Haugesund in March 2006, at a time when the large Ormen Lange and Snøhvit onshore plant projects were absorbing most of the available labor. Consequently, the yard found it difficult to recruit the extra staff it needed, and was obliged to recruit additional workers from abroad. As a result, efficiency was disappointing and productivity somewhat below expectations, Solli says.

The vessel eventually left the yard in February. After undergoing thruster installation and various trials in the deep waters of the Åmøy Fjord near Stavanger, it was hooked up to the buoy on the field in March.

Marathon appreciates the cooperation at government level. “We’ve had a very constructive relationship with the authorities — with the NPD, while preparing the PDO, the PSA [Petroleum Safety Authority of Norway] during execution, with the NMD [Norwegian Maritime Directorate] concerning the ship, and with the ministry itself,” says Færøvik. “They all are very accessible, and it’s not hard to find the right person to talk to.”