New study assesses E&P options in US outer continental shelf ice-covered waters

Dr. Mike Paulin, IMV Projects Atlantic

In January 2008, IMV Projects Atlantic (IMVPA) completed a study for the US Minerals Management Service (MMS) titled “Arctic Offshore Technology Assessment of Exploration and Production Option for Cold Regions of the US Outer Continental Shelf.”

Objective

The study objective was to assess oil and gas technology that may be applied to cold regions of the US outer continental shelf (OCS). Advances in harsh environment offshore exploration and production technology have made it economically and technically feasible for projects to proceed in ice-covered waters.

This study assessed the current state of offshore technology in arctic and sub-arctic regions. The results of this assessment then were used to provide insight and guidance into existing/future exploration and development technologies that might be applied on the US OCS, in particular those areas in the Beaufort, Chukchi, and Bering seas.

The work covers exploration structures, bottom-founded and fixed production concepts, floating production concepts, terminals, pipelines and subsea facilities, and also touches on other technologies that might be relevant to Alaskan OCS exploration and development.

This study draws on a review of current state-of-practice and state-of-the-art used in, or proposed for, arctic and sub-arctic offshore development areas. Assessments of exploration and production options are based primarily on technical feasibility. As appropriate, other aspects also have been considered, including constructability, capital costs, environmental considerations, operations, maintenance and repair, abandonment, and decommissioning.

Given the large geographic area encompassed by the Beaufort, Chukchi, and Bering seas, location scenarios were adopted to help focus the assessments. These locations were chosen based on current and historic activity and interest (including lease sales, drilling, studies, projects, etc.) and water depths (given the general differences in offshore facilities configuration with water depths). Overall applicability of the technology to the region of interest also was considered.

Technical feasibility

Bottom-founded structures

In multi-year ice areas of the Alaskan OCS, there are bottom-founded, e.g., gravity base structure (GBS), solutions that would be considered safe and economical to around 250 ft (75 m) water depths when foundation properties are good, and to around 200 ft (60 m) water depths when foundation properties are relatively weak.

There are no known bottom-founded platform design solutions for water depths greater than 330 ft (100 m) that could be deemed workable or proven for multi-year ice areas. In the more southern areas, where multi-year ice is absent and only first-year consolidated ridge loadings are possible, bottom-founded solutions out to 500 ft (150 m) water depths are potentially viable.

Jacket and jackup structures

The ice reinforced jacket platform was used successfully first in sea ice in the mid 1960s for Cook Inlet, Alaska, developments. Previous studies suggested that jacket structures are suitable for areas of the Bering Sea. However, these studies did not consider the vibration responses associated with the dynamic ice loading. Jacket type structures could likely be made to work in light first-year ice and in water depths less than 200 ft (60 m). However, the jacket structure’s potentially poor response to dynamic loading and the need for conductor system protection are significant design issues for application in the Bering Sea.

Current design practices and understanding of jacket design make their application unsuitable for the Beaufort and Chukchi seas.

Developments in jackup technology and the advancement of ice maintenance programs indicate that the operating range and season of jackup exploration could potentially be extended in the Bering Sea.

Ice islands

Grounded ice islands have been used successfully as exploration drilling structures in nearshore areas of the US and Canadian Beaufort Sea. In practice, operational ice islands have been employed in water depths of up to 25 ft (7.6 m) in the Beaufort Sea.

Based on previous work sponsored by the MMS, the use of operational ice islands might be achieved in water depths of up to 30 ft (9 m). This previous MMS Ice Island Study (2005) suggests that “incremental improvements in equipment capacity with higher productivity would allow islands to be constructed into deeper water and it is considered that 40 ft (12 m) water depth should not present a problem.”

The use of ice islands in the nearshore Chukchi would not likely be feasible due to the unstable and unreliable landfast, or contiguous, ice zone. Nor would ice islands generally be considered feasible for Norton Sound due to its warmer and shorter winter season. However, definite conclusions can only be reached through more detailed study.

Gravel islands

Although not a “high tech” solution, gravel islands have been used successfully in the Beaufort Sea for decades and continue to be viewed as a candidate structure for exploration and/or production in this area of the Alaskan OCS.

Since no gravel island has been used in the Chukchi Sea, a more detailed assessment is required to determine feasibility. Consideration would need to be given to the fact that the nearshore Chukchi Sea ice environment may be more dynamic than the Beaufort Sea. In the nearshore Bering Sea, gravel islands may be subject to higher waves and larger wave loads, which would need to be considered during detailed assessment.

Floating structures

There have been only a limited number of floating E&P structures used in ice environments. Seasonal exploration can be carried out in the Alaskan OCS using drillships and drilling barges and, in areas without multi-year ice, semisubmersibles, or a TLP. However, for exploration the only location that a floating structure might be capable of staying on station year-round might be the Bering Sea under light ice conditions. A semi-rigid floater structure might work year-round under first-year ice conditions but would need to have the ability to disconnect and leave station in the event of potentially higher loads.

Floating production systems for the Beaufort Sea, Chukchi Sea, and North Bering Sea are not considered technically feasible, even with continuous ice management. No floating production structures could be economically designed to stay on station with multi-year ice loads in the Beaufort and Chukchi seas, and possibly northern Bering Sea, depending on local ice conditions. Floating systems may have some merit in southern Alaskan OCS areas, however.

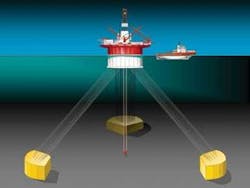

Subsea solutions

In some cases, there may not be a requirement for a production island or platform offshore. If the wellhead is in deep enough water, protection from ice would not be necessary. In areas with water depths less than the maximum ice keel depth, glory holes may be needed to protect the subsea facilities from ice keels.

Improvements in subsea facilities and processing have been made in recent years in the pursuit of resources in harsh and remote environments. As a result, fields requiring longer, deeper subsea tiebacks now are becoming much more technically and economically feasible. Gas tiebacks have reached 105 mi (170 km) and oil tiebacks have reached 40 mi (65 km).

Subsea facilities potentially can be considered for any development on the Alaskan OCS. However, there are limitations on which technology should be or would need to be considered. Glory holes would only offer protection from gouging keels. Where active ridge building is taking place or there are grounded ridges present, there is the potential for a ridge keel to be pushed into an open glory hole as the ridge keel is being formed. Beyond the zone of active gouging, subsea facilities might be placed directly on the seabed (depending on the ice gouging regime).

Pipelines & flowlines

Pipelines have been designed, constructed, and are operated in the arctic; but these are in relatively shallow water depths and relatively close to shore. Pushing the limits to developments further offshore in deeper water will require additional consideration to the design, construction, and operation.

Some of the main considerations for pipeline design in the arctic are strudel scour, thaw settlement of permafrost, upheaval buckling, and ice gouging. It is felt generally that the first three considerations can be designed for on future projects. However, pipeline burial for protection in water depths from approximately 65 to 130 ft (20 to 40 m) will be a challenge given the more severe gouging in these water depths and the fact that the pipeline can likely not be installed from the ice in winter. While trenching from the ice to a certain water depth has been proven on projects in the nearshore Beaufort Sea, trenching and pipeline installation from floating vessels has not been attempted.

Recommendations

It is agreed generally that environmental conditions (especially waves and ice) are changing in the arctic. But no one knows by how much, nor is there a compilation of current data (that the study team could find) that provides the information necessary to draw upon. It has been suggested by some stakeholders that future efforts compile, collect, and/or generate ice, metocean, and meteorological information to be used in future assessments.

For this study, the team identified information that would be “valuable to have” for future work. In addition, some technological areas were identified where advancements should be pursued, and these are also captured in this report. Full results of the study can be found atwww.mms.gov/tarprojects/584.htm.

Acknowledgements

This study was sponsored by the MMS through its Technology Assessment & Research Program. IMV Projects is part of the international energy services company, John Wood Group PLC (“Wood Group”). Other participants providing input to IMVPA in support of the study were: IMV Projects Inc.; CKJ Engineering Ltd.; Oceanic Consulting Corp.; K.J. Hewitt & Associates; Waterford Energy Systems Inc.; DC Marine Offshore Services Inc.; and CANATEC Associates International Ltd.

About the author

Dr. Michael Paulin is president of IMV Projects Atlantic (IMPVA), an engineering, procurement, and construction management company that is part of international energy services company, Wood Group. IMVPA focuses on development of offshore oil and gas resources in cold regions. Paulin’s most recent work includes a conceptual design for a mobile, ice resistant drilling rig for the Russian arctic, pipeline studies for the Canadian and US Beaufort Sea, and project management associated with pipelines offshore Sakhalin Island. He has received a doctorate degree in civil engineering (1998), master of engineering degree in ocean engineering (1992), and a bachelor of engineering degree in naval architectural engineering (1998), all from Memorial University of Newfoundland. He is a registered professional engineer (P.Eng.) with the Association of Professional Engineers and Geoscientists of Newfoundland and Labrador and a registered professional engineer (PE) in the state of Alaska. e-mail: [email protected]