Subsea gas compression technology nears reality

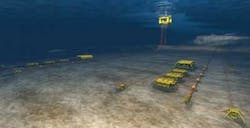

With subsea pumping and separation a reality, subsea gas compression is the next logical step in the development of subsea processing.

Developing the compressor for long-life in such harsh subsea environments is no small challenge, but the rewards are significant. In addition to the additional reserves that can be recovered, subsea gas compression could save 30 -- 40% over the cost of surface developments.

FMC Technologies and Siemens Industrial Turbomachinery are working with several customers to fund and to establish industry interest for the development of this technology. Among the ongoing efforts, is testing of the Siemens compressor at Statoil’s Asgard Minimum Flow Project. Statoil’s goal is to have two 6-8 MW compressors in 250 m (820 ft) of water powered from and connected back to the Asgard B platform to boost gas production from two nearby fields.

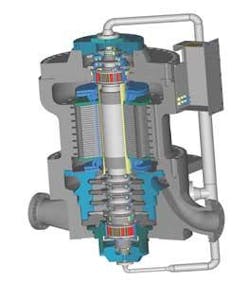

Several qualification activities are under way for the Asgard project subsea gas compression control system. These include the gas scrubber, compressor control system, the actual compressor, and process coolers.

FMC and Siemens plan to develop and market an electrically-driven, centrifugal gas compressor for operation in water depths up to 3,000 m (9,842 ft) that will be capable of operating for several years without requiring maintenance. Depending upon application need, FMC says this could be available to the market in the 2011-2013 time range.

“Both companies view subsea gas compression as one of the most interesting technologies for the future and are taking a leading role in its development,” says Rune Fantoft, manager Technology, Subsea Process Systems at FMC. “The development of subsea gas compression technology will help operators increase overall recovery from maturing fields for a lower cost. The potential is significant, especially when compared with similar topside solutions. In addition, remote fields with long transport distances to production units can be enabled by the use of this technology.

“Together, we are working on the technologies needed for FMC to offer a complete subsea gas compression system in the market with the use of a Siemens compression unit,” Fantoft says. “Siemens is providing the gas compressor technology as well as being an engineering partner for FMC on the development of the overall subsea gas compression system. FMC, on the other hand, is actively involved in the development and qualification of the fully marinized subsea gas compression unit.”

The main issue in subsea compression verses topsides is the requirement for compressor reliability. Topside compressors today generally have an auxiliary system that requires supervision and maintenance. Obviously to be successful, a subsea system would need to work without access for years.

Beyond this, in principle there are no limits to the distances for which subsea compression is applicable except for power distribution and control system communications. FMC says it has tested successfully a control system communications technology that can work at several hundred kilometers. That means the power distribution may be the limiting factor at present. Power comes from either a host platform or from shore and is located with the system controls.

The most likely scenario for subsea compression is for high volumes of dry gas. The flow rate, in combination with the boosting requirements and distance from the host are the major cost factors. The boosting requirements will determine how man megawatts of compression are needed. In turn, that will determine how many compression trains are required. The distance from the host, again, will determine the power system design.

While dry gas may be the best-case, it is not the only case. A gas-liquid scrubber can handle the incoming flow transients and demist the liquid to meet compressor requirements. FMC says it has called upon its subsidiary CDS Engineering to provide separation technology for safe compressor operation.

Subsea processing is gaining market acceptance and is making its way into the toolbox of oil and gas companies for field development. In addition, subsea liquid/multiphase boosting, separation, and water injection are technologies that are now available as field development building blocks. In fact, the world’s first integrated subsea separation, pumping, and sand handling system has been delivered by FMC for Statoil’s Tordis project this summer and will be set in operation later this year.

“We believe subsea gas compression is a natural following application,” Fantoft says.