Riserless mud recovery moves into deepwater

Roger Stave, Richard R. Brainard, P.E., John C. Cohen, P.E. - AGR Subsea Inc.

The advantages of a riserless mud recovery system have been limited to shallower waters until recently. Now, a joint industry project with a focus on the Gulf of Mexico is addressing the use of such systems and their advantages.

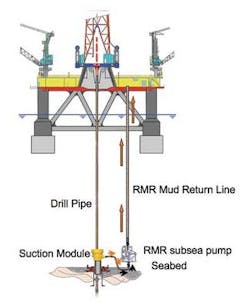

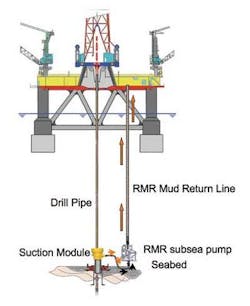

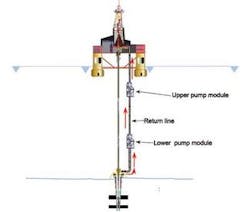

AGR Subsea Inc. has modified its Riserless Mud Recovery (RMR) technology with a subsea disc pump on the Cutting Transport System (CTS) qualified for use in deepwater.

AGR’s RMR technology has been used around the world in the last four years to drill shallow water tophole sections in water depths less than 1,500 ft (450 m). A modification of AGR’s CTS, a technology using subsea pumps to move well cuttings away from the subsea templates, now allows drill mud and cuttings to be returned from the subsea wellhead to the rig with a subsea disc pump qualified for use in water depths to 1,500 ft (450 m). RMR technology is portable, can be used on most jackup or floater rigs, interfaces with the driller, and requires little rig-up time. The equipment has exhibited reliability, with less than 2% downtime.

Attention now is turning to advance this technology for both deepwater and ultra deepwater operations, with specific focus on use in the Gulf of Mexico (GoM). An RMR Demo 2000 Deep Water JIP has been initiated and is being funded by two operators, Shell International Exploration and Production, Inc. and BP America Production Co. Additional funding is by Demo 2000, a Norwegian government technology support organization, as well as AGR Inc. A field trial of the advanced technology is expected to proceed in 3Q 2008 offshore Malaysia in approximately 4,800 ft (1,400 m) of water.

This technology imparts a dual gradient effect in the wellbore to allow drilling between narrow pore/fracture pressure gradient profiles. In addition, successful new uses have included zero discharge of drilling fluid for wells offshore the Barents Sea, offshore Sakhalin, and Australia’s northwest shelf for environmental benefits, elimination of seabed discharges. Although most applications of this technology have been with floaters, a recent jackup operation offshore Egypt showed reduced well costs when using this technology allowed deletion of a shallow liner. The operator realized cost savings in excess of $2 million.

Typical tophole drilling in the deepwater and ultra deepwater GoM is done using water-based fluids under “pump and dump” operations. Mud and cuttings are not recovered, but discharged and spread on the seabed around the wellhead. Use of this RMR technology would return cuttings and mud to the rig from the wellhead, providing benefits in well construction and in reduced environmental impact.

Well construction benefits

Using this technology in well construction may allow the operator to:

- Extend shallow casing depths past trouble zones

- Reduce number of casing strings

- Establish more predictable casing setting depths

- Improved wellbore stability

- Mitigate shallow hazards

- Reduce drilling fluid volumes

- Reduce cement volumes

- Reduce in logistics costs

- Reduce drilling time and associated costs.

The major benefits of using this technology in deepwater and ultra deepwater applications are savings in well construction time and cost, including the ability to:

- Eliminate one or more large diameter casing strings

- Downsize post-BOP casing strings to more conventional sizes

- Eliminate or reduce under reaming (required for close tolerance casing designs)

- Eliminate or reduce in frequency of remedial cement squeezing of surface casing.

Well construction cost savings typically come from dual-gradient effects resulting in a bottomhole pressure profile that more closely matches the well’s pore/fracture pressure gradient. This technology also provides more predictable penetration to proposed casing setting depths, and cementing of casing at planned depths mitigates the need for contingent strings.

Better engineered fluids

The operator’s ability to return drilling fluid to the rig allows the use of better engineered fluids to drill the riserless hole sections. These fluids can be engineered to improve hole stability and hole cleaning, and to reduce washout. It also may reduce the associated logistical resources necessary to transfer the liquid mud volumes. Additionally, this technology will enable the use of salt-saturated drilling fluid systems in shallow salt formations within the riserless hole sections. During conventional operations, salt-saturated fluids are cut on the fly with seawater and lose their salt saturation while being pumped down the hole. This results in wash-out of the salt formation which makes cementing more difficult and costly, and may affecting other factors such as hole spiral and impaired directional control.

Shallow hazard mitigation

The enhanced mitigation of shallow hazards while using RMR will provide additional benefits on locations with moderate to high shallow water or gas flow potential. This system provides enhanced monitoring of influxes into hole sections. Identifying shallow flows more quickly means applying remedial techniques, including an increase in mud weight, sooner to mitigate wellbore damage. An additional aspect of this technology is the ability to use conventional managed pressure drilling (MPD) equipment such as a subsea rotating control device. This allows additional pressure control at the mudline during operations. The addition of this equipment in conjunction with the suction module would not be for handling well control operations as with conventional BOP equipment, but rather to add the ability to suppress or limit additional flow into the wellbore while circulating heavier mud to control pressures and flow. This technology facilitates a closed managed pressure system to apply pressure on the annulus during drilling or tripping and to provide a physical separation of the drilling fluid with a natural hydrocarbon contaminated influx from mixing with the open sea. Mitigation measures to prevent entry of gas into the mud return line need to be similarly addressed as will not exceeding a safe margin of pressure based on the fracture gradient of the previously set shoe.

Additional benefits may include reduced cement volume in more gauge shallow hole sections and improved cement job quality with less susceptibility to flow after cementing because of better hydraulic isolation of the wellbore/casing annulus.

Environmental benefits

This technology can provide several environmental benefits including:

- Minimized drilling fluid volumes

- Reduced discharge of cuttings and drilling fluid to the sea at the seabed

- Eliminated discharge of naturally occurring liquid hydrocarbons to the seabed

- Protection of chemosynthetic or coral communities from nearby seabed fluid discharges.

AGR’s RMR system enables the cuttings and mud to be returned to the rig for separation. The fluid is recycled and the cuttings disposed in a controlled manner. For environmentally sensitive areas, the fluid may be slurrified and reinjected, or shipped to shore for disposal. For some exploration wells, the slurry might be able to be injected in the well prior to permanent plugging. These methods enable meeting stringent discharge legislation by eliminating almost all discharges to the sea.

Overall drilling fluid program discharges may be reduced to no more than 25% of typical “pump and dump” volumes, along with associated reductions in emissions from the supply boats. Additionally, reductions in exhaust emissions of the tugs/barges and trucks required to transport the basic fluid components such as barite, salt, gel, and drill water to the fluid processing facilities at the major deepwater bases will be obtained.

In some instances naturally occurring weathered hydrocarbons may be associated with salt structures in the shallower intervals near the sea bed. Currently in the GoM, discharges are made to the seabed under approved general permit conditions. Any departure due to hydrocarbon contaminated fluids must be approved specifically. Due to inability to use a riser with a pin connector with the low fracture gradients in the GoM and the absence of other technology, use of RMR under these conditions would return hydrocarbons to the rig for onshore disposal.

Borehole benefits

Additional benefits that this technology has shown include no or minimal wash-out of wellbores drilled with inhibitive fluids. This has resulted in improved cementing operations and quality, along with a reduction in flow after cementing. This technology also allows a continuous flow check of open hole sections through its control system. Recovering the mud and cuttings to the rig allows an operator to obtain geological information from these shallower tophole sections. Monitoring of shallow hole cementing job(s) with the RMR pump instrumentation is expected to provide a better idea of actual hole volumes with improved displacement efficiency planning.

Evaluation tools

AGR is preparing evaluation tools to simulate the application of this technology on deepwater wells. These tools include use of AGR Petroleum Service’s P1 software, the probabilistic planning tool designed to improve well planning and construction. P1 has become a planning tool for many large operators and underpins AGR Petroleum Services’ offering. This tool provides probabilistic analysis of the well construction and costs, and can evaluate the potential inclusion of this technology into the shallow well program. P1 has been developed specifically to improve well construction performance. The use of the software and the associated procedures ensure that all risks and opportunities can be examined thoroughly and transparently in the well design phase, with times and well costs viewed as a range of likely outcomes. The system allows informed decisions to be made on all aspects of planning, from the conceptual phase to the finished well.

P1 provides a rigorous, standardized, systematic approach to many of the key elements of successful well construction, such as:

- Probabilistic time estimating

- Probabilistic cost estimating

- Risk quantification and mitigation

- Statistically credible option selection

- Standardization across wells, projects and business units.

Well design

Other ways in which RMR drilling may save time and cost depend on:

- Pore/fracture pressure gradient curve for shallow hole section

- Distribution of well types for multi-well project

- Ability to design wells with reduced shallow hole and post-BOP casing sizes

- Historical distribution of hole interval costs (include all rig days in excess of drilling to clean, displace, run casing, cement, WOC)

- Estimated qualitative shallow flow risk for each hole section, well type, and required mitigation actions

- Estimated reduction in deeper well hole sections duration and costs if the number of shallow hole casing sizes can be reduced. Although an operator may not make specific reductions in the original casing program after an in initial RMR job, demonstrated reliability and success allows an operator to consider these changes in a systematic manner with successful use of this technology over a period of time and well types.

There are potential mud cost and rig time reduction for RMR in deepwater or ultra deepwater. For this consideration the following will need to be assessed:

- Historical distribution of liquid weighted mud volumes used on pump and dump jobs

- Historical distribution of duration spent on pump and dump operations in days or hours

- Average number of hole sections employing pump and dump

- Historical distribution of mud volumes used on jobs

- Average cost of liquid mud

- Average deployment and recovery tripping speeds for mud return riser (ft/hr), including control umbilical

- Average total rig spread rate ($/day or $/hour).

Logistics

Logistics costs can be significant. The following need to be assessed:

- Historical distribution of volumes of liquid mud transported to rig

- Average size capacity of liquid mud handling supply vessel

- Number of mud handling supply vessels required during pump and dump operations

- Average charter rate ($/day) for and number of liquid mud work/supply vessels required

- Average weather or other delays (hours or days) when unable to transfer mud from boats to rig

- Average costs to clean mud handling work/supply vessel after jobs, including associated charter time (hours or days) during cleaning.

Other parameters may provide savings to a deepwater or ultra deepwater project. The following need to be assessed:

- Reduction in number of re-spud wells due to mechanical loss in shallow hole section (wells per 100 wells or percent lost)

- Reduction in number of re-spud wells due to flow after cementing (wells that are eventually junked due to ineffective isolation -- wells per 100 wells or percent lost)

- Historical distribution of re-spud well costs.

These application parameters can be applied to deepwater or ultra deepwater GoM with this technology to deliver additional benefits in this environment such as the use of salt saturated muds. However, continued demonstration of system reliability and reduction in online deployment and retrieval time will be critical to the success in today’s high cost environment.