Performance evaluation of Ormen Lange subsea compression concepts

Remi Eriksen, Fredrik Gustavsson - DNV Consulting; Edwin Poorte, Shell Technology Norway; Bernt Bjerkreim, Hydro

Developing Ormen Lange, the first deepwater discovery to be developed offshore Norway, represents a major challenge with a combination of water depth, extremely rough seabed conditions, long tieback distance, and demanding weather conditions. Fully developed, the Ormen Lange production system will consist of 24 subsea wells and multiphase transport to an onshore gas treatment terminal at Nyhamna. Gas export will be to Easington (UK) via the 1200-km long Langeled pipeline. Hydro is operator for Ormen Lange in the development phase. Norske Shell will take over operatorship at first production.

The Ormen Lange field is located 120 km from the West Coast of Norway at a depth ranging from 800-1,100 m. First gas is planned for 2007 with an expected need for offshore compression in about 2014.

A subsea gas compression system is currently being evaluated as an alternative to topside compression on a floater. Subsea compression on Ormen Lange would represent a major technological advancement for subsea processing systems, as both the required step-out distance for power (120 km), the total installed power (exceeding 50 MW), and the system throughput (some 60 Mcm/d) are an order of magnitude larger than existing subsea processing systems in operation to date. The Ormen Lange license is currently executing the “Maturing of Technology Phase” of a multi-year technology qualification program.

Subsea compression is a novel and unproven technology, but with great potential for Ormen Lange to reduce capex compared to a floater with topside compression. To capture this potential, investments are required to qualify the economical feasibility of the technology and to manage the uncertainty in the qualification process. This paper will identify areas of uncertainty related to subsea compression technology and define a rational approach to support the decision-making process in the qualification of subsea compression solutions. We also explore what might be a good balance between high production availability requirements and low lifecycle cost.

Introduction

Field development profitability is a function of many income and lifecycle cost factors such as capital expenditures (capex), operating expenditures (opex), production rate, product price, frequency of component failures, and intervention vessel expenses. Component failures reduce the field total production rate and increase opex. Regardless of the chosen concept, the ability to efficiently keep production onstream is one of the most important factors determining field economic performance.

The lost revenue due to failures and the associated intervention and repair costs is expressed in the term risk expenditures (riskex). Integrating capex, revenue, opex, riskex, and HSE issues will provide a sound basis for finding the best solution for future compression on Ormen Lange.

Hydro and Norske Shell are working closely together on a technology qualification effort that is executed by Hydro as part of the Ormen Lange project. This program consists of the following phases:

- technology maturation (2004-2005)

- engineering, procurement and construction of a pilot system (2006-2008)

- submerged testing of the pilot system for an extended period (2009-2010).

The timing of the technology qualification program was chosen such that, when successful, it allows Ormen Lange to select subsea compression as the base case for offshore compression. To date, the base case offshore compression concept is a topside solution on a newbuild floater (this represents the concept that was submitted to the Norwegian authorities at time of final investment decision for the Ormen Lange development).

Ormen Lange license partners are Hydro, Norske Shell, Petoro, Statoil, Dong, and ExxonMobil.

For the Ormen Lange subsea development, the lifecycle field economies are estimated with a simulation approach capturing the future performance of various subsea compression alternatives. We illustrate for the early project phase how to estimate the cost associated with future unplanned interventions caused by component failures (riskex) - both direct intervention expenditures and the value of lost revenue.

Achieving high production availability is important for all gas developments, both from a security of supply perspective and from a return on investment perspective.

In theory, 100% production availability might be achieved by immediate and perfect interventions of any incipient failures. Alternatively, one might invest upfront in a larger-than-required production capacity.

In practice, 100% availability is not feasible or justified from an economical point of view, due to the time associated with vessel mobilization and repair activities as well as considerable intervention costs.

Modularization options have been explored that could meet the required production availability target, while achieving favorably low lifecycle costs. The study was done in such a way that qualitatively correct conclusions could be drawn, even if many of the underlying reliability data for technology elements (e.g., mean time-to-failure statistics) is at present not known with sufficient accuracy.

Field development concept

The subsea-to-land concept for Ormen Lange was chosen in preference to a more traditional deepwater concept with an offshore processing facility with wet and/or dry wells (spar, TLP, or semi), putting more emphasis on the management of reliability and maintainability of downhole, well, and subsea equipment.

The fully developed Ormen Lange production system consists of 24 subsea wells and multiphase transport (two off 30-in. flowlines) to an onshore terminal at Nyhamna. Four templates are supplied with electrical/optical/hydraulic control from two umbilicals, which are interconnected with a crossover umbilical allowing control to be supplied through the other neighboring template if needed (see Figure 1). Sales gas is exported to Easington (UK) through the 1200-km Langeled pipeline.

null

Subsea compression concepts

The subsea gas compression solutions studied include the following:

- long step-out power supply (120 km offset, 70 MVA, 120 kV)

- subsea power distribution to 22-kV level (circuit breakers, variable speed drives)

- four off 12.5 MW centrifugal gas compressors with gas-filled, high-speed motors, and magnetic bearings

- four off liquid pumps

- four off separators

- other equipment (coolers, control system, instrumentation, valves, process piping, various connections).

The subsea compression system for Ormen Lange analyzed in the present work consists of two templates with two compression trains on each. A generic system arrangement is illustrated in Fig. 2.

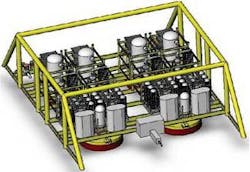

For the purposes of this study, the subsea compression system is divided into maintenance packages (or retrievable units). Each maintenance package can be retrieved/replaced using a suitable intervention vessel depending on weight and geometrical size.

Three different modularization alternatives (Cases 1, 2, and 3) were studied. These differ in the way in which power distribution and rotating equipment is made retrievable.

- Case 1 has a relatively large number of not-so-heavy modules and hence a large number of wet mateable connectors

- Case 3 has a relatively small number of modules, some of which are heavy (300 MT), but a small number of wet mateable connectors

- Case 2 is in-between Case 1 and 3.

Case 1 has, to a large extent, split the system to achieve small and light packages to reduce the number of the heavy lift operations, resulting in low vessel mobilization time and low cost per intervention. The downside of this design is the increased number of wet mateable connections, which might reduce overall system reliability.

Cases 2 and 3 have bigger and heavier maintenance packages, reducing the amount of wet mateable connections in the system (potentially more reliable, but more costly interventions and longer vessel mobilization times). Power supply is provided by a single umbilical that is dry-connected to a main step-down transformer. This means that the transformer and umbilical end cannot be retrieved separately, but must be retrieved in combination. The power supply is the most critical element in the whole system as any failure in umbilical, termination, or transformer might result in total loss of compression capability. For this reason, the availability requirement on the long step-out power supply is very high.

System performance

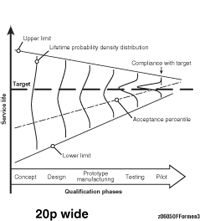

At this stage in the technology qualification process, the knowledge of the reliability statistics of various subsea compression elements is limited. The aim of the qualification program is to ensure that production availability is at an acceptable level. In addition, the uncertainty in the estimate must be reduced during the qualification process (Fig. 3). Further, the qualification can be used to identify the optimal sparing/redundancy level, modularization level, and intervention strategy.

A performance model was developed to predict system availability performance and the direct costs associated with potential interventions. These performance parameters will be factored into overall net present value evaluations. The performance model has been used to identify and rank contributors to production unavailability and intervention cost, which form the basis for identifying cost-efficient improvement measures for the subsea compression system.

This performance evaluation study is one step in the technology qualification program, i.e., quantifying the uncertainties in a field life perspective and identifying key drivers of production unavailability and intervention cost.

The present study uses the following steps to quantify unplanned operating expenditures (riskex):

- Develop a component reliability model. A failure mode and effect analysis can be used to perform a systematic, hierarchical system breakdown, and to identify component failure modes and their associated effects on the system level

- Develop a system reliability model to combine individual component failures to overall system reliability (accounting for redundancy, correlation structure between component failure modes, and maintenance strategy)

- Develop a system downtime model for the site-specific field development scheme on the basis of the classes of events included in the system reliability model. This is based on:

- -characterization of the effects on production continuity deriving from each class of events in terms of loss/reduction of production or loss/reduction of expected incremental production

- -characterization of the scenario of availability for marine vessels and equipment in and outside the region of interest, suitable to perform the intervention operations associated with each class of identified events

- -development of a vessel availability model based on categorization of lead-time depending on vessel requirements for various failure events, as well as categorization of lead-time depending on contractual situation (vessel on call-out basis or vessel under long term contract)

- -development of the overall downtime duration model through the breakdown and evaluation of individual operational steps including marine equipment mobilization, transit to site, equipment retrieval and re-deployment, system recommissioning and startup

- Determine the cost associated with loss/ reduction of production and intervention activity based on:

- -production rate forecasts

- -loss in revenue by not producing the planned volume (based on gas price and production/transportation cost structure)

- -mobilization cost and vessel day rate (spread cost).

For calculation purposes a Monte Carlo simulation technique has been used. A Monte Carlo (stochastic) simulation is carried out by generating discrete events in a computer model (sampled from relevant probability distributions) in order to create a realistic or “typical” lifetime scenario of the system components. The software simulation package Extend Version 6 has been used in this project.

Each activity in the model is started and terminated by an event. For instance, an intervention is an activity, which begins with a failure, then goes into a waiting period for a suitable repair vessel, and a shut-in period due to the repair activity itself, and ends with a recovery of production.

The simulation is treated as a series of real experiments. Statistics that describe the reliability, availability, and maintainability performance (e.g., annual production availability, average annual deferred production, and annual riskex) are calculated by suitable averaging of the simulated realizations of the system lifetime.

The deferred volume is calculated according to the formula below:

Deferred volume per event = (demand capacity - capacity after failure) X vessel waiting time + (demand capacity - capacity during repair) X repair time

Typical results

For each of the three cases, a number of sensitivities were run. Some sensitivities explore the effect of being able to qualify failure-prone elements to high reliability. Others evaluate the effect of having an intervention vessel on permanent standby (thus dramatically reducing mobilization time). Also, a number of sensitivities with different overcapacities were evaluated.

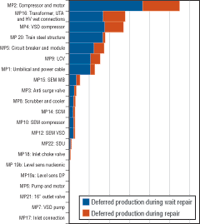

Figure 4 shows the yearly deferred production caused by each maintenance package. The blue area shows the production loss due to vessel waiting time (wait repair) and the red area shows the production loss due to the intervention/repair activity itself. For all maintenance packages, the production loss due to vessel waiting time is the main contributor.

From the figure it can also be seen that the production lost due to vessel waiting time is relatively higher for interventions undertaken by a cable lay or heavy lift vessel than for interventions that can be undertaken by a multi-purpose support vessel.

There are many parameters to evaluate in this pre-feasibility process. One way to summarize the information is to present the results in a three-dimensional risk matrix. For example, a bubble plot may be generated that would show for all maintenance packages:

- number of interventions per year (x-axis)

- cost per intervention (y-axis)

- deferred volume per intervention (size of bubble).

The most critical components would have large bubbles and would be positioned in the upper right corner (i.e., highest number of interventions at the highest cost per intervention).

Conclusions

This paper describes the approach to integrate intervention and availability considerations into the decision-making process for selecting and optimizing the subsea gas compression system on Ormen Lange. The work undertaken by the Ormen Lange project has focused on evaluating the lifecycle economics for a number of compression trains and modularization alternatives. For example, smaller maintenance packages allow for smaller intervention vessels, but have reduced system reliability when compared with larger maintenance packages requiring bigger intervention vessels (with higher spread cost) and that have increased system reliability due to less wet matable connections.

The optimal system architecture for subsea compression was found to depend on:

- intrinsic reliability of technology elements

- degree of overcapacity in the system

- choice of modularization

- repair vessel mobilization time

- repair vessel day rate.

The main findings of this study were as follows:

- Having a vessel available for quick mobilization will significantly increase production availability (at a certain cost)

- Increasing production capacity beyond the design capacity is useful up to a certain point where additional capacity increase gives diminishing returns, as the common mode failure in power supply from shore starts dominating the remaining unavailability

- A quantified risk matrix was generated that helps guide the qualification process, as it allows the project team to focus on the largest contributors to failure frequency, cost per intervention, and deferred production per failure

- There was no one modularization option that was always the best compromise for all studied sensitivities. This is due to field-specific or regional factors (e.g., vessel availability). Hence the optimal architecture for modularization of a subsea processing system is not a universal choice, but is case-specific (both in terms of seabed processing functionality and in terms of field-specific factors).

Acknowledgement

The authors would like to thank Hydro and Norske Shell for the permission to publish this paper. We would also like to express our appreciation to everybody involved in the Ormen Lange Subsea Compression Project.

This paper was prepared for presentation at the 2005 Deep Offshore Technology Exhibition held in Vitória, Brazil, Nov. 8-10, 2005.