ExxonMobil meets deepwater Nigeria development schedule

Production exceeds 200,000 b/d of oil

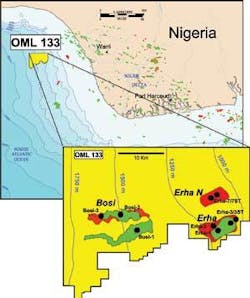

With the flow of first oil from its third drilling center, ExxonMobil’s Erha/Erha North development offshore Nigeria in water depths up to 1,750 m entered a new phase. As of September, oil production was exceeding 200,000 b/d and injecting 225 Mcf/d of gas plus 80,000 b/d of water.

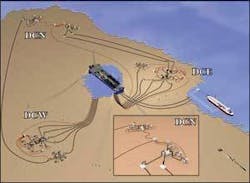

Production is into an FPSO with a SPM offloading buoy. The FPSO, one of the largest in the world, is designed to store 2.2 MMbbl of oil and to handle 210,000 b/d of oil plus 340 Mcf/d of gas for reinjection and 150,000 b/d of water reinjection. Production is from three subsea centers - Erha DCE, DCW, and DCN. The first two centers have a total of 24 wells. Of that, 15 are producers, 4 are water injection, and 5 are gas injection. DCN has 8 wells, 4 each for production and water injection. Development drilling began in November 2003 and continues.

Several firsts were recorded with Erha. These including the first fabrication of subsea manifolds in Nigeria and the first Subsea Systems Integration Test (SSIT) in Nigeria and West Africa and was conducted at Willbros Yard in Port Harcourt, Rivers State, a facility that can now serve as a regional center for future subsea component testing for global deepwater development projects. Other local content includes the SPM for tanker offloading at a rate of 1 MMb/d of oil at Nigerdock, Cameron’s construction of a subsea operations support base at Onne, pile fabrication, subsea jumpers at Globestar in Warri and FPSO flare tower and piperacks at SCNL in Port Harcourt.

The entire project involved resources from around the world in order to meet the schedule. The facility installation and final equipment testing was done in Nigeria; project management and design engineering was accomplished in Houston, Paris, New Delhi, and Lagos; trees, controls, and umbilicals in England, Germany, and Norway; compressors and generators in Italy; and construction in Nigeria, South Korea, Singapore, and Malaysia.

ExxonMobil’s affiliate, Esso E&P Nigeria Ltd. is the operator of the Erha developments and has a 56.25% participating interest in the OML 133 production sharing contract area, with Shell Nigeria E&P Co. holding the remaining 43.75%.

Erha is one of three major facility startups for ExxonMobil affiliates in Nigeria this year.

In February, Mobil Producing Nigeria Unlimited (MPN) started production from the full-field facilities of the Yoho project, with estimated recoverable resources of 440 MMbbl of oil.

Yoho is producing about 160,000 b/d of oil, and consists of a central production processing platform, 33 wells, living quarters platform, and an FSO vessel.

In July, the company announced the startup of the Additional Oil Recovery (AOR) project, that is expected to produce 530 million gross barrels of additional oil reserves from blocks OML 67 and OML 70, and will provide a peak volume of 120,000 b/d of oil. The development will further reduce routine flaring at the facilities to help meet the Nigerian government and ExxonMobils’ goals. Like the Erha and Yoho developments, the AOR project also contained significant Nigerian content.