Reducing drilling costs in ultra-deepwater locations

As the oil and gas industry matures, so does its technology and equipment. And as a drilling rig gets older, it becomes increasingly challenging to use to explore for untapped deep reserves. Offshore rig builders manufacture rigs with new, sophisticated capabilities, thereby widening the technology gap between the new rigs and the aging ones. As a result, many operators of older rigs are modifying them to compete with newer ones.

Unocal Indonesia is a pioneer of surface stack drilling with second- and third-generation rigs in deepwater. When adding the environmental safeguard (ESG) device (a means of closing a well and disconnecting if a riser failure occurs) and solid expandable tubular technology to a proven surface stack drilling technology, a synergy emerges. The combination of these three technologies enables an operator to drill a wellbore to total depth in ultra-deepwater that would have been possible previously only by using a fourth- or fifth-generation rig. After several successful implementations, this combination of new technologies and smaller rigs is proving to be a reliable means of reducing drilling costs in ultra-deepwater locations.

Surface BOP operation

Simply defined, surface BOP operation is the practice of using a floating drilling unit fitted with a BOP that is suspended above the waterline in the moonpool area. The BOP, usually a land/jackup type BOP, is connected to a high-pressure riser serving as a conduit to the sea floor.

Typically, the high-pressure riser is 13 3/8 in. casing deployed in one continuous length from the casing shoe to the surface wellhead. The equipment configuration is similar to a jackup with added top tension, except the vessel is floating and the water depth may be thousands of feet deep.

While surface BOP drilling is not a new concept, the technology to take the concept into ultra deepwater began about seven years ago offshore Indonesia. The surface BOP concept for this program was initially deployed to drill inexpensive exploration wells in a benign environment in water depths between 100-500 ft. The operation was successful and proved that several days time could be saved compared to conventional subsea operations.

The concept was further refined to go into deeper waters. The factors contributing to lower per-well costs in a relatively benign sea conditions include the following:

• A mooring system using a taut wire type mooring can go into greater water depths than normal

• A pre-laid mooring system significantly reduces the time required to move the drilling unit between locations

• With low-heave requirements, a doubler sheave can be added to each riser tensioner, doubling the effective line tension while halving the line stroke

• With the surface casing used as the high-pressure riser, the structural casing requirements are greatly reduced

• The running, testing, and retrieving time of the subsea BOP is saved

• All well control activities are performed at the surface BOP, which is accessible for maintenance and simplifies testing

• The operator has access to a wider selection of drilling units, lower spread costs, and fewer operating days per well, all of which occurs with little exposure to subsea-related downtime.

Design criteria

The evolution of offshore floating drilling guidelines and standards are specific to the traditional subsea BOP and low-pressure riser drilling systems, primarily to implement these guidelines and standards in a fit-all-applications approach. Very few floating drilling systems have ventured outside this norm. A thorough review of surface BOP technology indicates this method can be applied in various environments safely if the proper safeguards are in place and the operating procedures address all likely contingencies.

The number of drilling barriers is a primary issue for surface BOP operations. Operating companies must feel comfortable with the wellbore pressures to use the surface BOP system without an ESG. For those locations where the wellbore pressures warrant, the ESG system can be made available.

Casing is the most common type of riser used for surface BOP applications in the Far East. A casing riser is ideal because it is used once as a riser and is then used as casing the next time around. In this way, new casing is always used for riser purposes, with a new reference for fatigue life calculation. For short wells and low dynamic riser stresses, this is a practical riser approach. However, for longer well duration, higher dynamic riser stresses, and greater top tension requirements, designing an appropriate fatigue life for the riser using casing connections may be difficult. For these applications, purpose-built riser may be desirable.

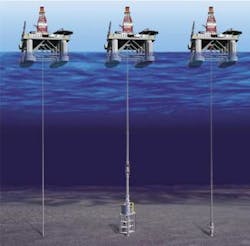

ESG

Drilling offshore using a surface BOP stack alone does not allow a practical means of disconnection in the event of an emergency. Also, if the riser is damaged while drilling, fluids in the riser can escape to the environment. However, when an ESG is included with the surface BOP drilling system, additional protection is realized. The ESG has the capability to shear, seal, and disconnect from the seabed, while the traditional surface BOP stack handles all the well control functions.

The ESG consists of upper and lower wellhead connectors, a ram-type BOP with a single set of shearing blind rams, and a control system. The control system works in acoustic mode and with a remotely operated vehicle (ROV) control panel as a back-up. The ESG is tied back to a traditional surface BOP stack with a high-pressure riser system.

Should it be necessary, the control system signals the subsea BOP to shear the pipe. Once the shearing blind rams shear and seal off the wellbore, the control system signals the upper connector to disconnect, allowing the rig to move safely off location with minimal loss of drilling or well fluids. When compared to a traditional subsea BOP stack, the ESG is considerably smaller and lighter and can be used in water depths up to 10,000 ft with a second- or third-generation rig. The system does not require umbilicals between the rig and seabed, and it allows several means of reconnection, including reconnection with a wellhead for production.

Environmental implications

Operators currently use second- and third-generation rigs with surface BOPs to drill in benign environmental areas. A benign environment is one in which the maximum design environment (wind, wave, tide, and current) allows for offsets and heave to accommodate the reduced riser tensioner stroke, even if one mooring line is damaged. Surface BOP operations are ideally suited to areas where relatively benign environmental conditions prevail.

Moderate environmental conditions require the full riser tensioner stroke to accommodate expected heave, tidal change, and vessel offset in the event of a broken mooring line. While not a hard rule, in general, these are the main differences that are found when reviewing areas normally considered benign and moderate for surface BOP operations. In many of the moderate environment areas of the world during certain times of the year, the maximum design conditions cannot be met. For these areas, it is recommended that a means to disconnect at the seafloor be incorporated into the riser system to prevent possible loss of the high-pressure riser. Since the ESG provides this means of disconnect, drilling with surface stack technology can now be considered a viable option for drilling in environmentally less benign areas such as the Gulf of Mexico, West Africa, Brazil, and the Mediterranean.

There are considerations other than weather for having a disconnect point at the seabed. The disconnecting capability of the ESG allows for temporary abandonment of the well. The well can be considered for production at a later time because of the ability to reconnect with a production-type wellhead. Flexibility is the key to making this possible. From a well construction aspect, a pressure isolation ESG system at the seafloor could also prove to be a safety device if higher than expected pore pressures are encountered. In this case, if these pressures were circulated to the surface, it may exceed the high-pressure riser rating. The ESG would act as an additional barrier for the wellbore at the seafloor, providing a means to close the well while other plans are implemented.

Expandable tubular

The underlying concept of solid expandable tubular technology is cold-working the steel downhole to the required size. The expandable casing string is run in the hole on an inner-string with a launcher assembly containing the expansion cone. Fluid is pumped down the workstring. The force of hydraulic pressure pushes the cone up the casing, thereby expanding the casing. Expandable casing is nominally sized API L-80 jointed casing that is manufactured to more exacting specifications. The use of electrical resistance welded material results in a uniform wall thickness, and additional steps in the manufacturing process provides the material properties necessary to allow expansion of the pipe without rupture failure.

The expanded openhole liner effectively creates an intermediate size of casing compared to conventional casing sizes. It is run in much the same way as conventional liners and for the same purpose, but allows the operator to increase final hole size for a given number of casing strings. The expandable liner has elastomer seals bonded to the outside diameter. During expansion completion, these elastomer seals are compressed between the expandable pipe and the base casing in the overlap. The compression of the seals creates a hanger for the expanded liner as well as an effective pressure seal at the liner top. No anchoring is required prior to the top hanger section being expanded.

Cost

Although each technology is cost-effective by itself, significant cost savings can be obtained by combining surface stack drilling technology, the environmental safeguard system, and solid expandable tubular technology in ultra-deepwater environments. A key contributor to these savings is the use of second- and third-generation rigs instead of fourth- and fifth-generation rigs. Several factors contribute to cost savings:

• Casing can be used for a high-pressure riser with a surface stack system on second- and third-generation rigs instead of a full low-pressure riser system on fourth- and fifth-generation rigs

• Mobilization costs are less for second- and third-generation rigs

• The daily cost of second- and third-generation rigs is 30% to 40% less than that for later generation rigs. Typically, a fifth generation drilling rig would cost up to $200,000/day whereas, this cost would drop to as little as $80,000/day for a third generation drilling rig

• Fuel consumption is less on smaller rigs

• Total volumes of mud are less because of smaller hole size

• Bit costs are less because of smaller hole sizes

• Casing costs are less because a number of strings have been eliminated due to this combination of technology

• The cost of using a surface stack and ESG is less than that for a full subsea stack and riser system

• Fewer rig days are needed because fewer initial casing stings are run, and there are faster rates of penetration when drilling smaller holes. Surface BOP drilling methods can cut the average number of days to drill a well by 50%

• Reduced non-productive time from having the BOP at the surface, which enables maintenance and repairs without having to retrieve it from the sea floor.

Case history

Total performed the first implementation of the ESG using a surface stack BOP in East Kalimantan, Indonesia. TheSedco 601 rig drilled an exploratory well in more than 6,000 ft (1,828 m) of water. The planned total depth for the well was 13,000 ft (3,960 m).

After performing a quantitative risk assessment on the project, the operator concluded that the use of the ESG would be safer than conventional surface stack drilling. In addition, the operator wanted to test the environmental safe guard on this well and evaluate its capabilities. If proven successful, Total planned to use the ESG with surface stack drilling technology in other areas.

The operator began drilling the well using a 13 3/8 in. riser and encountered several challenges. To avoid penetrating a shallow gas zone without a riser, the 13 3/8 in. conventional casing had to be set higher than expected. Following a kick while drilling the next hole section, the 11 3/4 in. liner was set prematurely and cemented at approximately 8,300 ft. The operator now had several alternatives if he chose to move forward with conventional technology. The first alternative involved drilling ahead and setting the 9 5/8 in. casing followed by the 7 in. casing string. After setting a 7 in. casing higher than was called for in the well plan, the operator would have had to drill deeper using smaller casing sizes. The smaller hole would have to be drilled using slimhole tools, with their inherent problems, including a smaller inside diameter at TD and the difficulty of formation evaluation such as logging and testing. The second option was to plug and abandon the well and continue the exploration in a different area. A potential third alternative was to start with a larger conventional casing size in order to maintain adequate hole size in the target zone. Unfortunately, the size of the rig limited the larger conventional casing alternatives available to the operator.

A 1,300-ft string of 9 5/8 x 11 3/4 in. solid expandable openhole liner was run to depth and set at approximately 9,400 ft. Liner expansion was performed using hydraulic pressure applied down the drillstring, forcing the expansion cone up the liner. As each stand of drillpipe was removed from the hole, the pressure was bled off, the stand broken out, and racked back in the derrick. Then, the top drive was reconnected and the upward expansion was resumed. This process was repeated until the entire expandable casing liner had been expanded and sealed into the base casing. Once the openhole liner was successfully expanded, it was pressure tested to 1,000 psi for 30 min. The expansion cone was then pulled out of the hole, and the float shoe was drilled out.

The installation of this expandable liner enabled the operator to get back on the original well plan and reach the target zone with adequate wellbore size.

Editor’s Note:This is a summary of SPE 90830 presented at the September 2004 ATCE