Shell sets world record with Coulomb tieback

Last of Na Kika on production

Jaime Kammerzell

Gulf of Mexico Editor

With an increasing number of new prospects in the deep-water Gulf of Mexico, operators continue to improve equip- ment, shorten project time, and set records. Shell began producing natural gas from its Coulomb development in June. The field boasts the two deepest-water subsea wells in the world. The company set the deepwater record while also setting a new drilling and completions time record.

Shell discovered the Coulomb field in 1988 with the C-1 well in 7,600 ft of water in the Mississippi Canyon area of the Gulf of Mexico. At that time, the company determined that Coulomb did not hold enough hydrocarbons to make development economical and plugged and abandoned the well.

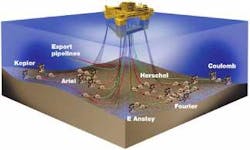

Coulomb remained P&A'd until Shell and BP began executing the Na Kika project in 2000. The Na Kika central production facility consists of a semisubmersible production unit moored in 6,350 ft of water, the deepest for any installation of its type in the world. In its entirety, the Na Kika development consists of five independent fields – Kepler, Ariel, Fourier, Herschel, and East Anstey – which Shell and BP have developed in a 50/50 joint venture with the installation of a centrally located, permanently moored semisubmersible floating development and production facility. The Kepler, Ariel, and Herschel fields mostly are oil, while the Fourier and East Anstey fields largely are gas. The sixth field, Coulomb, is primarily owned by Shell, with Petrobras holding one-third interest in the C-3 well. BP and Shell went through an extended appraisal program to put together a sufficient number of fields with adequate volumes of hydrocarbons to make Na Kika's development economical.

"Coulomb is the one field that pushed it over the edge for Shell to make the entire development worthwhile," Kent Stingl, Na Kika project manager, says.

null

Project planning

Shell determined the plan for the Coulomb field when the Na Kika project was sanctioned.

"At Shell we agreed that [Coulomb] would be a two-well development tied back to the Na Kika host facility," Stingl says.

The C-2 well is in Mississippi Canyon block 657 in 7,565 ft of water, and the C-3 is in block 613 in 7,570 ft of water, 27-mi to the southeast of the Na Kika host.

The biggest challenge at Coulomb was the 7,600-ft water depth. "We had drilled wells in that water depth, but never completed wells at that depth," Stingl says.

Mooring of the rigs in the record-setting water depth proved to be a challenge. Shell used the ultra-deepwater Transocean Nautilus semisubmersible, moored with suction piles. Even in the calmest waters, there is a certain amount of movement with a moored rig. Shell carefully designed the development plan to avoid hurricane season and project-delaying ocean currents.

One of the biggest challenges Shell faced was in designing the company's standard subsea hardware – subsea wellheads, well jumpers, connectors, and umbilicals. The hardware had never been subjected to the high hydrostatic pressures at 7,570 ft of water. Normally, Shell designs subsea pressure-containing equipment to hold pressure from the inside, Stingl explains. "But this one we had to design or make modifications to the equipment to prevent sea water from flowing into the system. At 7,600-ft water depth, you have over 3,500 psi of hydrostatic head – that is, the weight of the column of water. So we had to design connectors and valves to hold the pressures from the inside and levels from the outside," Stingl says.

Shell faced similar challenges while laying the 27-mi umbilicals and 8-in. uninsulated flowline.

"At this water depth, when first initiating the pipe, you have tremendous loads, because of the weight of the pipe hanging from the flowline installation vessel," Stingl says.

Shell upgraded the flowline installation vessel, Technip Offshore Construction's Deep Blue to handle the weight of the pipe, and did the same for the umbilical installation vessel, Subsea 7's Toisa Perseus.

"The deeper the well is, the heavier the pipe is, and the more competent your mechanical systems need to be," Stingl says.

Coulomb is mainly a dry gas development. "From a flow assurance standpoint, Coulomb is not as complicated as other Na Kika oil wells," Stingl says.

Shell's primary hy-drate management strat- egy is to continuously inhibit gas with mono-ethylene glycol (MEG). The MEG is injected via the umbilical into the tree. Shell produces the gas back with the MEG to inhibit the gas from forming hydrates.

Shell installed a tree on the C-2 and C-3 wells using its heave compensated landing system (HCLS), lowering the 10,000-psi production equipment 7,600 ft using the Casey Chouest AHV, which executed the HCLS. The operation is done offline from the rig, which could save as much as $1 million on each well, Shell estimates.

The C-2 and C-3 are single wells with wet gas meters. The two connect into a single flowline sled via jumpers. The Oceaneering Ocean Intervention II installed the two-well jumpers and wet gas meters. The wet-gas meters sit on the jumpers to meter production from the well individually before it is commingled in the flowline. Coulomb marks the first time Shell used wet-gas meters.

For the record

Coulomb set several world records and achieved a number of firsts for Shell. The Coulomb project also marks the first time the Transocean Nautilus performed completion operations. Previously it had only done drilling.

"We had to get the crew out of a drilling mentality into a completion mentality," Stingl says. "We brought the crew in and had completion awareness training to show the crews what completion operations were all about, what the equipment was like, and how important it was that the completion fluids were clean."

null

Shell also set a record for speed, completing drilling and completion operations 34 days ahead of schedule. Shell completed the C-2 well in 13 days ( 1 day ahead of schedule) and the C-3 in 17 days (8 days ahead of schedule).

"I think the efficiency of the rig had a lot to do with [finishing ahead of schedule]," Stingl says. "The fact that we could install the trees, tubing heads, and lock-down sleeves offline of the rig, and the completion awareness training saved time."

Shell's drilling and completions teams perform a technical limit exercise for each project. All of the crew members get together and wrote the completion procedure to determine the technical limit of each procedure. The fastest time a procedure can be accomplished becomes the goal. After each operation is complete, the crew reviews the operation and learns from it.

On production

The Coulomb wells are producing at a combined rate of 85 MMcf/d, but are capable of reaching 120 MMcf/d. Coulomb is restrained to 85 MMcf/d because Na Kika has reached its capacity.

"All of the Na Kika fields are online, and production is steady and meets expectations, Stingl says. "We are looking at increasing the capacity of the facility. Shell has conducted a technical exercise on what we can produce and be comfortable with. BP and Shell will conduct a second review to determine what modifications are needed to increase capacity even more."