Seismic analysis used in pipeline design

Qiang Bai

Wenjun Zeng

Li Tao

OPE Inc.

Seismic ground waves produce strains in buried pipelines. However, because there are little or no inertia effects from dynamic excitation, the strains tend to be small and often are well within the yield rupture threshold of the pipeline material. The direct effect of seismic waves is, therefore, generally not expected to cause rupture or buckling failure to buried pipelines.

Nonetheless, seismic waves can cause damage to unburied pipeline systems, especially in the interfacing area, such as in the pipeline transition section from buried-to-unburied and the pipeline tie-in spool to the subsequent structure. In general, the seismic analyses of the permanent ground deformation for buried pipes and unburied pipes, and seismic ground waves for unburied pipes are required for designing pipeline systems. Offshore pipelines are normally buried for stability and mechanical protection; otherwise they are laid on the seabed.

Seismic design methodology

Several seismic analysis approaches for pipeline design were developed to predict the pipeline behavior in response to differential ground movements. Two main structural response models were considered:

- Static model for buried pipelines subjected to fault crossing due to soil failure

- Dynamic analysis model for unburied pipelines subjected to ground wave load.

Fault crossing is one of the major hazards to offshore pipelines, whether buried or unburied. Numerous investigations have been carried out for fault crossing with different soil movements. The pipeline's ability to deform in the plastic range under tension helps prevent rupture at fault crossings. If compression of the pipeline in a fault crossing is unavoidable, the compressive strain should be limited to within the local buckling criteria.

The amount and type of ground surface displacement is the main factor for designing pipelines to resist permanent ground deformation at fault crossings. Bonilla summarized a simple equation relating the maximum displacement at ground surface to the earthquake surface-wave magnitude as log L = -6.35 + 0.93Ms, where L is the maximum surface displacement in meters and Ms is the earthquake surface-wave magnitude.

The earthquake magnitude is one of the design criteria based on the historical seismicity and geological data. Displacement data from the fault of similar earthquakes might be used in selecting a value for designing pipelines because of a big deviation in earthquake surface displacement data on which the equation is based.

Two typical analytical methods under certain assumptions were suggested for the fault crossing analysis, Newmark-Hall and Kennedy. Kennedy and others extended the ideas of Newmark and Hall and incorporated some improvements in the method for evaluating the maximum axial strain. They considered the effects of lateral interaction in their analyses. The influence of large axial strains on the pipe's bending stiffness is also considered. O'Rourke and Liu reported that the Kennedy model for strike slip faulting, which results in axial tension, provides the best match to finite element results, based on an independent comparison of the available analytical approaches.

Abaqus is the selected program to develop finite element models of ground soil, pipelines, and subsea manifold connection because of its capability to accurately simulate solid objects, pipes, elbows, material, and geometric non-linearities, and interactions between soil and pipelines. The software also provides analytical models to describe the pipe-soil interaction. These models describe the elastic and perfectly plastic behavior by defining the force exerted on the pipeline and its displacement.

The ASCE guidelines give a detailed description of both the Newmark-Hall and Kennedy schemes. It must be emphasized that both schemes are only valid for pipe under tension, since this condition may not be guaranteed under other various combined modes of fault movement.

Due to the largely non-linear nature of the problem, a finite element analysis (FEA) is the most general tool for pipeline fault crossing design. Non-linear finite element modeling allows accurate determination of pipeline stress/strain at various locations along the pipeline route with a wide range of parameters. The pipe-soil interaction can be modeled as discrete springs in three dimensions. The pipeline is represented as a sequence of finite straight beam elements supported on the bottom by the bearing springs. The imposed fault movement is then input into the FEA model as a static displacement boundary condition. The analysis is performed to determine the equilibrium nodal position of the pipe, bending moment, axial force, strains, and stresses.

Ground wave analysis

Both permanent ground deformation and seismic ground wave can cause severe damages to unburied pipelines and connected equipments. There are three basic methods available for analyzing the responses of a structure subjected to seismic ground wave:

- Static analysis

- Response spectra analysis

- Time history analysis.

In general, a static analysis is sufficient for the long-term response of a structure to applied loads. However, if the duration of the applied load is short, such as in the case of an earthquake event, a time history dynamic analysis is required.

Under static analysis, the pipeline is divided into individual spans or into a series of segments. Static seismic loads are considered to be in direct proportion to the weight of pipe segments. The peak acceleration from the response spectrum is applied as a lateral force distributed along the pipe and bending stresses and support reactions are calculated. The seismic static coefficients are usually obtained from the seismic "zone," which corresponds to a level of seismic acceleration. Many design software programs can perform static analysis, but these methods are primarily used in building seismic design.

In response, spectra analysis, the ground motion versus frequency method, is used. The maximum acceleration for a given frequency and damping is determined based on seismic maps and soil characteristics. The higher the damping, the lower its acceleration. The responses of displacements (translations and rotations), loads (forces and moments), and stresses at each point for each natural frequency of the system and for each direction are obtained after analysis. The calculated loads, displacements, and stresses of the piping system are typically calculated by taking the square root sum of squares of the response in each of the three directions. The response spectra method is approximate, but is often a useful, inexpensive method for preliminary design studies.

The time history analysis method involves the actual solution of the dynamic equation of motion throughout the duration of the applied load and subsequent system vibration, providing a true simulation of the system response at all times. In time history analysis, the seismic time history ground motions (displacement, velocity, or acceleration as a function of time) of seismic ground waves in three directions are applied to a finite element model of a system to obtain time history excitations of the system, including stresses, strains, and reaction forces. Time history analysis is a more accurate, more computationally intensive method than response spectrum analysis and is best suit-ed to the transient loadings where the profile is known.

Seismic level of design

Two design levels are normally adopted for the design criteria, contingency design earthquake (CDE) and probable design earth- quake (PDE).

null

The CDE represents a higher-level earthquake, established on the basis of a geo-seismic evaluation with a typical return period of 200-1,000 yr for pipelines. The intensity of CDE is taken as the design limits, exceeding causes of pipe failure, or at least sufficient damage to cause an interruption of service. On the other hand, the PDE is a lower level earthquake, which assumes only minor damages to the pipeline system without interrupting the service. These events are likely to occur during the life of the pipeline and are therefore incorporated as part of the design environmental load. PDE is usually taken to have a return period of 50-100 yr.

Analysis examples

To explore the seismic responses of offshore pipeline systems, two study examples are presented here:

- Static response of a 42-in. buried pipeline to permanent ground deformations where the pipeline is fully buried under the natural seabed

- Dynamic response of a 42-in. unburied pipeline system to seismic waves where the pipeline is laid on the seabed and connected to a subsea manifold.

null

Buried pipeline responses for a fault crossing

A buried steel pipeline with a 42-in. diameter and a 0.875-in. wall thickness, material of API 5L Grade-X65, contains oil at a specific gravity of 0.8. The pipeline is backfilled with a 3-ft sand depth median, with a density of 120 lb/cu ft and a friction angle of 35°.

This sketch shows a buried pipeline under a fault crossing due to an earthquake. The fault length in the plan direction ΔY is set as 1.2 m, in the vertical direction, with ΔZ set as 1 m. The unanchored length varies depending on the pipeline size and axial pipe-soil interaction force (friction force). The 1,000 m long pipeline, with both ends fixed, is modeled by using pipe elements in the example.

Non-linear pipeline-soil interactions in axial, lateral, and vertical directions are modeled with pipe-soil interaction elements and soil characteristics in ft-xt, fp-yp, and fq-zq force-deformation curves. Based on the formulas suggested in the ASCE guidelines, the maximum axial interaction force per unit length at the pipe-soil interface (ft is 36.6 kN/m, and corresponding maximum deformation, xt) is 0.004 m. The maximum lateral interaction force per unit length (fp is 175.4 kN/m and corresponding maximum deformation, yp) is 0.08 m. The maximum upward interaction force per unit length fq is 38 kN/m and corresponding maximum deformation zq is 0.044 m. The maximum downward interaction force per unit length fq is 1,450 kN/m and corresponding maximum deformation zq is 0.13 m.

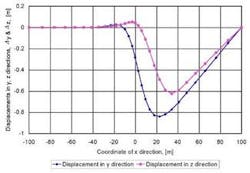

The line graph shows the displacements of the pipeline in y and z directions under the fault crossing. The maximum stress exceeds 80% of SMYS of the pipe, which is within ASME criteria. Therefore, the designed buried pipeline is not suitable for the seismic level, which can cause inputted fault distances.

Sensitivity calculations of different buried depths of the pipeline also show that the maximum stress and strain of the pipeline are proportional to the buried depth, when other parameters are the same. To decrease the damage of the pipeline, in the possible area of the seismic fault cross, the pipeline should not be buried.

Responses of unburied pipelines for a ground wave

A seismic dynamic analysis was performed for an offshore pipeline system. This analysis consisted of two 42 in. OD x 0.875 in. WT (API X65 pipelines) and a 300-metric-ton subsea manifold. The pipelines contained oil at a specific gravity of 0.8 with an internal pressure of 600 psi. A settlement of 0.1 m for the subsea manifold, due to sand liquefaction in the earthquake, is considered.

In the Abaqus model, the subsea manifold was modeled as a solid box. The straight and curved pipeline sections were modeled as 3D beam elements and elbow elements, respectively. The seabed was modeled as a rigid surface with frictions in both longitudinal and lateral directions. The pipeline-soil interaction was modeled by a linear contact pressure relationship. The accelerations in three directions were applied to the seabed. The maximum Von Mises stress of 191.9 MPa (27.8 ksi) occurs at the spools.

A time history of maximum Von Mises stresses shows it always occurs in the spool areas. The difference of natural frequencies and weights for the subsea manifold and pipelines causes the response difference between subsea manifold and pipelines. Therefore, the maximum stress occurs in the spool areas.

Analysis assists in design

This seismic design and analysis methodology was developed for offshore pipeline design. It has been successfully applied in seismic analyses of buried pipelines under fault crossing and unburied pipelines with a subsea manifold by using a static analysis and a dynamic time history analysis. The sensitivity analysis results show that the buried depth of buried pipeline and the soil stiffness in the pipeline-soil interaction are the primary factors affecting pipeline stress in an earthquake. As discussed, the seismic analysis within this technical note is intended for assistance in developing seismic analysis and design guidelines for offshore pipelines.

References

ASCE, 1984, "Guidelines for the Seismic Design of Oil and Gas Pipeline Systems".

ASCE, 2001, "Guideline for the Design of Buried Steel Pipe".

ASCE, 2002, "Seismic Design and Retrofit of Piping Systems".

ASME B31.4, 1998, "Pipeline Transportation System for Liquid Hydrocarbons and Liquids".

Bai, Y., 2003, "Marine Structural Design", Elsevier.

Bonilla, M. G., 1982, "Evaluation of Potential Surface Faulting and other Tectonic Deformation", Open File Report 82-732, U.S. Geological Survey.

DNV-OS-F101DNV, 2000, "Submarine Pipeline Systems", Det Norske Veritas.

Kennedy, R. P., Chow, A. W., and Williamson, R. A., 1977, "Fault Movement Effects on Buried Oil Pipeline", Journal of the Transportation Engineering Division, ASCE, Vo. 103, No. TE5, pp. 617-633.

Newmark, N. M. and Hall, W. J., 1975, "Pipeline Design to Resist Large Fault Displacements", Proc. US National Conference on Earthquake Engineering, Ann Arbor, Michigan.

O'Rourke, M. J. and Liu, X., 1999, "Response of Buried Pipelines Subject to Earthquake Effects", Monograph No. 3, Multidisciplinary Center for Earthquake Engineering Research.

Authors

Li Tao, P.E. is the engineering manager for OPE Inc. His experience includes 14 years in offshore project management, engineering, and installation. [email protected]

Wenjun Zeng, Ph.D., is a subsea analyst for OPE Inc. His experience includes riser stress and fatigue analysis, offshore pipeline design and installation, and finite element analysis. [email protected]

Qiang Bai , Ph.D., brings more than 10 years' engineering/research experience to OPE Inc. as senior pipeline engineer. His experience includes flow assurance, subsea pipeline and riser systems mechanical design, and finite element analysis (FEA) of subsea structures and flowlines. [email protected]