Humid air motor system achieves 80% cut in diesel NOx emissions

Air quality improvement continues to be a major goal for engine makers and engine users around the world. Regulatory auth- orities are tightening emission standards with the purpose of removing reactive pollutants from the air.

Diesel engines used in shipping account for 21% of all the nitrous oxide (NOx) production in Sweden. Only road vehicles at 34% and off-road activity at 23% created more NOx in a 1997 study. Broken down by transportation type, shipping contributed 36% of NOx emissions with road-based transport producing the bulk at 59%; air transport produced 3% of NOx emissions.

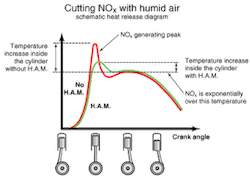

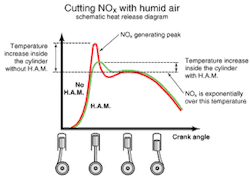

To help overcome this, Munters developed the humid air motor system (H.A.M.), which uses water vapor-saturated air to reduce NOx emissions by 60-80%. The key to the effectiveness of the H.A.M. system is that it reduces hot spots in the diesel engine without harming the engine's efficiency. Combustion flamefront is slowed to a more uniform combustion temperature and more mass flows through the cylinders, which in turn maintains, or even gives the potential to increase, the energy efficiency of the engine. As the graph shows, NOx is created when the cylinder temperature spikes at the top of the compression cycle. With the H.A.M. system, this peak is reduced, eliminating a large proportion of the potential NOx that could form.

In the complete installation, waste heat from the engine is captured to heat water in order to evaporate water vapor. This vapor is fed into the combustion air, which provides NOx control. For ocean vessels, seawater can be used to reduce the cost of the operation. A side-benefit is that the engine's exhaust valves have less thermal stress and also the combustion chamber is much cleaner and saves lubrication oil.

For more information, contact Jan Wettergard, Munters. Tel: +46 8 626 6352, fax: +46 8 754 5666, email: [email protected].

null