Magnetic resonance imaging logging (MRIL) data has been acquired in a deepwater Gulf of Mexico field to delineate hydrocarbon-bearing zones where conventional techniques intro-duced uncertainties in fluid type, hydrocarbon saturation, and rock texture. Processing tech- niques such as time domain analysis and the diff-erential spectrum method were applied to quan-tify pore fluid volumes and permeability. The Free Fluid (or Coates-Timur) model was used to com-pute permeability throughout all zones. The strong correlation in this field between pore body and pore throat dimensions enabled the use of the tool for such permeability estimates.

The MRIL while drilling (MRIL-WD) tool parameters are compared to those derived from the wireline tool, illustrating the impact that tool selection has on log results. For ease of processing and interpretation, the logging while drilling (LWD) tool was designed to be equivalent to the wireline tool.

Determine viable replacement

One objective of this test was to determine if the MRIL-WD tool would be a viable replacement for the wireline instrument (MRIL-Prime) in difficult wireline logging environments. This determination is important because it minimizes the risk in deep and deviated wells, with the added benefit of the rig cost savings. Other benefits would be:

- The acquisition of nuclear magnetic resonance (NMR) data on the movable-fluid volume with reduced invasion effects

- The possibility of performing time-lapse logging in combination with MRIL-Prime

- Collecting NMR data for much larger intervals than typically logged by wireline.

Objectives for NMR logging

The field development team had the following objectives for NMR logging:

- Determining accurate permeability values in an area where simple porosity-permeability relationships from conventional logging data are inaccurate

- Confirming total porosity (PHIT) and irreducible water saturation (SWIRR) evaluation results from conventional LWD logging data

- Characterization of hydrocarbon type.

Several challenges

The development team faced several challenges as these objectives were merged with constraints in drilling the well:

- The large 10 5/8-in. borehole diameter could impact logging results and tool selection

- All conventional data (resistivity/sonic/ density/neutron/gamma ray) was gathered in the LWD mode

- The well was deep (20,000 ft) and deviated (maximum deviation -50°).

Background

Before a formation is logged with the tool, the protons in the formation fluids are randomly oriented. When the tool passes through the formation, it generates magnetic fields that activate those protons. First, the spin axes of the protons tend to align at a certain angle to the direction of the permanent magnetic field of the tool and precess around this direction at their Larmor frequency.

The tool's oscillating field is then applied to tip these protons away from their new equilibrium position. When the oscillating field is subsequently removed, the protons begin tipping back, or relaxing, toward the direction of the permanent magnetic field. This process is referred to as T1 relaxation.

At the same time, local variations (on a molecular scale) of the magnetic field will cause slight variations of the Larmor frequency. As a result, the phase coherence of the precessing spins will slowly vanish. This process is called T2 relaxation.

To measure T2 relaxation, a specific pulse sequence is used to generate a series of spin-echoes, which are measured by the logging tool and are displayed on logs as spin-echo trains. These spin-echo trains constitute the raw data. The observed spin-echo train is related to both data acquisition parameters and properties of the pore fluids located in the measured volumes.

Data acquisition parameters include inter-echo spacing (TE) and polarization time (TW). TE is the time between the individual echoes in an echo train. TW is the time between the cessation of measurement of one echo train and the beginning of measurement of the next echo train. Both TE and TW can be adjusted to change the information content of the acquired data.

MRIL devices are sensitive to the total number of hydrogen atoms that are in the liquid or gaseous state, and as such provides a lithology-independent porosity measurement as long as the hydrogen index of the fluids can be estimated.

Data acquisition parameters

The unique capability of the tool to measure multiple rock and fluid properties needed for prospect evaluation and reservoir modeling requires multiple measurements on the "same" volume using different acquisition parameters (activations). These different activations can usually be used during the same logging run with the wireline tool and, to a lesser extent, with the MRIL-WD. Two activation sets were used in the subject well: total porosity and dual TW.

The total porosity activation set acquires two echo trains to obtain the total porosity MSIG. To acquire one of the echo trains, the tool uses TE = 1.2 ms and a long TW to achieve complete polarization. This echo train provides the effective porosity MPHI. To acquire the second echo train, the tool uses TE = 0.6 ms and a short TW that is only long enough to achieve complete polarization of the fluids in the small pores. The second echo train is designed to provide the porosity associated with claybound water.

The dual-TW activation of the MRIL-Prime runs is primarily used to identify light hydrocarbons (gas and light oil). The water signal is contained in both activations, but light hydrocarbons (which have longer polarization times) have a greatly suppressed signal in the TW = 1 s activation. The presence of a signal in the difference of the measurements is a very strong indicator of gas or light oils. In this well, measurements were made with TW = 1 and 12 s and TE = 1.2 ms.

The job planner is a modeling tool used for appropriate tool parameter selection in which assumptions are made for the expected rock and fluid properties. The use of the planner is a critical step in the execution of every MRIL job, tailoring the acquisition parameters to improve the chance of obtaining reliable results. If acquisition parameters are not properly selected, processed outputs may provide properties that differ greatly from the actual reservoir properties.

In this well, a 1,000 echo, single TE, dual TW activation was selected for the MRIL-Prime, along with a sequence to quantify total porosity and the volume of clay bound water.

For the MRIL-WD run, a 200-echo single TE, single TW activation was chosen. As in the case for the MRIL-Prime, a total porosity sequence was implemented; however, this sequence was interspersed in the single frequency available for MRIL-WD operation.

Tool hardware

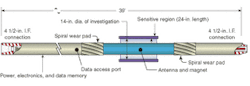

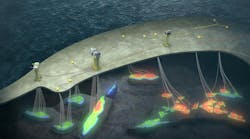

The bottomhole assembly (BHA) for the MRIL-WD run consists of two main sections: a lower sensor section and an upper electronics section. The sensor section contains the permanent magnet and flow tube, located in the collar, as well as the antenna, while the electronics sensor houses the batteries, power control, processing, memory, and the radio frequency transmitter and receiver. Readout ports are included to enable programming of the tool prior to tripping in the hole and retrieval of raw echo data at the end of the logging run.

The prototype tool used in this well had a battery life of 70 hours and was therefore run as a memory-only device (no real-time data transmission to the surface). It was also limited to a TW = 3 s activation due to programming constraints at the time of job callout. The new commercial tool has a battery life of 200 hours and is capable of real-time data transmission.

Field operations

The MRIL-Prime was run on drillpipe in combination with the formation-testing tool. Following formation testing operations, the MRIL-Prime was logged across the zones of interest at a logging speed of 8 ft/min.

Due to the previously mentioned constraints on battery life, the MRIL-WD was run after wireline logging during the well conditioning pipe trip. After assembling and programming the MRIL-WD tool at the surface, the BHA was run in the well, and logging commenced when the zones of interest were reached. All zones were logged while pulling the BHA up at 1 ft/min. This logging speed was selected to allow adequate polarization of formation fluids while minimizing noise and maximizing vertical resolution. To minimize rig time, only intervals of interest identified by previous conventional LWD log interpretation were logged with the MRIL-WD tool.

Initial analysis

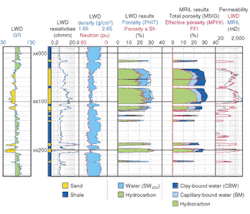

Initial analysis of LWD logs caused concern due to several factors:

- The sand distribution differs markedly from the discovery well

- The upper channel (depth interval xx032-xx140) has a ratty character and appears to be shalier than the clean sands in the channel below (depth interval xx180-xx208)

- The neutron and density porosity curves show separation characteristic of shaly or laminated sands

- The high density-porosity readings.

All of these characteristics indicated that the reservoir in this well was of a poorer quality than the discovery well.

As in many deepwater Gulf of Mexico wells, the first development well has to produce at high rates, approximately 20,000 b/d with 1,000 gas-to-oil (GOR) ratio to be economically viable. Based on the discouraging initial petrophysical analysis the development team was forced to choose between completing the zone of interest and re-drilling the well to another target.

MRIL-Prime analysis

The MRIL analysis indicated the formation had good porosity, permeability, and saturations that could provide a justification for completing the well in this zone. However, it was recognized that uncertainties in hydrocarbon type and hole conditions could have resulted in the overestimation of porosity.

The MRIL results provided an independent source for total porosity and permeability estimates and confirmed the previous interpretation of reservoir properties, allowing the development team to recommend completing the well in the interval. The MRIL played a crucial role in reducing the uncertainties in fluid type and supporting previous porosity data. The MRIL analysis predicted water-free production from the zone with permeabilities ranging from 400 to 1,000 md. The PHIT from the MRIL-Prime agrees closely with the PHIT from hydrocarbon-corrected density porosity, while the value of irreducible water saturation (SWIRR) is lower than the sum of the clay bound and capillary bound fluid.

Production results of 27,000 b/d and 1,250 GOR confirmed the combined petrophysical analysis of the LWD and MRIL data.

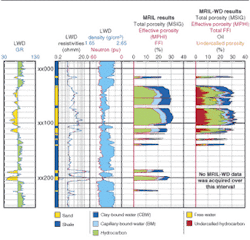

Closely matched data

The MRIL-WD closely matched the MRIL-Prime data. However, the constraint of running with a single TW only limited its ability to satisfactorily perform hydrocarbon typing. Free fluid volumes were under-estimated because the short TW did not provide enough time for complete polarization between echo trains. However, the use of the total porosity from the conventional LWD data compensated for this under-call. Cross-plots indicate the reasonable match with MRIL-Prime for the clay-bound and capillary-bound fluid yielded by the MRIL-WD.

Conclusion

The combined evaluation of LWD and MRIL data provided the complete information required for decision-making and proved to be essential in accomplishing team objectives.

The current version of the MRIL-WD has multiple frequency-bands that allow for dual TW activations and longer TWs that will overcome the porosity undercall experienced in the subject well. It is expected that this tool will become a standard component of the project team's LWD suite.

Acknowledgments

The authors wish to thank John Stachowiak, Shell E&P Co.; Justin Freeman and Matthias Appel, Shell E&P Technology Applications and Research; S. Menger, Numar, and J. Witkosky and K. Huggins, Halliburton Energy Services, for their assistance in processing and analyzing the data.

References

Coates, G.R., Xiao, L., Prammer, M.G., et al. 1999, NMR Logging principles & applications, Gulf Publishing Co., Houston, Texas.

Fukushima, E., and Roeder, S.B.W. 1981, Experimental pulse NMR: A nuts and bolts approach, Addison-Wesley Publishing Co., Advanced Book Program, Reading, Massachusetts.

Prammer, M.G., et al. 1996, Measurements of clay-bound water and total porosity by magnetic resonance logging, SPE 36522, 1996 SPE Annual Technical Conference and Exhibition Proceedings. Also published in 1996 in The Log Analyst, v. 37, no. 5, p. 61-69.

Prammer, M.G., et al. 1998, A new multiband generation of NMR logging tools, SPE 49011, 1996 SPE Annual Technical Conference and Exhibition Proceedings.

Prammer, M.G., et al. 2000, Field test of an experimental NMR LWD device, 2000 SPWLA Forty-First Annual Logging Symposium Transactions.

Authors

Glenn Donovan is a Senior Technical Advisor for Halliburton Energy Services in New Orleans, Louisiana. He obtained his BS in mechanical engineering at Duke University in 1975. He has worked in the US Gulf of Mexico, South America, and the North Sea as a field engineer and manager and is currently responsible for MRIL and MRIL-WD interpretation.

Gustavo Ugueto C. is a senior staff petrophysical engineer at Shell Exploration and Production Co. in New Orleans. He graduated with a degree in geological engineering from Universidad Central de Venezuela in 1982 and began his work as a petrophysical engineer at Petroleos de Venezuela SA. He joined Shell in 1988 and worked as a petrophysical engineer in The Hague and London prior to being named discipline head of petrophysical engineering in Shell Brunei.

Nicky Pellerin is an account representative for the Sperry-Sun product line of Halliburton Energy Services in New Orleans where he is responsible for LWD services at Shell Offshore. He received his BS in petroleum engineering technology from Nicholls State University in 1987 and worked as field engineer in the US Gulf of Mexico prior to his current assignment.