Terje Myhr

Statoil

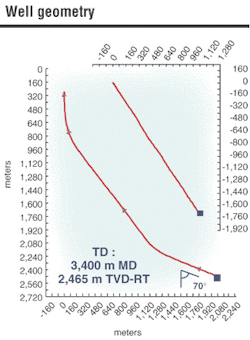

Earlier this year, the 8 1/2-in. open hole section in the Z-3H well in the Midgard Field off mid-Norway was logged using Welltec's wireline well tractor as the conveyance method. This was the first such application of its type in Europe for this device, and the first ever deployment from a semisubmersible rig.

The tractor's ability to perform logging on wireline led to savings of 55 hours on rig time for this project, equivalent to NKr 6 million.

Simulations based on the well trajectory, combined with experience from other wells in this area, led to the conclusion that the 8 1/2-in. reservoir section on Z-3H would necessitate use of drill pipe (TLC) as the conveyance method for open hole data acquisition. Including a tractor in the wireline logging string would provide the necessary force to push the toolstring to total depth (TD) of the section.

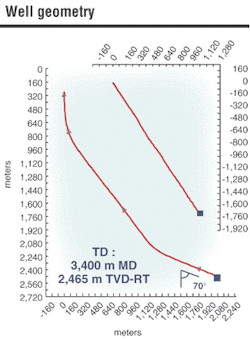

One major challenge during planning of this operation was the length of the 12 1/4-in. rat hole. The extending arms on the tractor's drive section could only extend to a maximum hole diameter of 10.2-in. Due to the length of the 12 1/4-in. rat hole – 10 m – the tractor might not be able to drive through this section. The solution was to include two tractors, separated by a spacer sub, in the logging string. This set-up could accommodate a rat hole length of up to 16 m.

The first tool string run in hole (including sonic and resistivity measurements) had a total length of 51 m. The assembly slid down by means of gravity to a position 150 m above the casing shoe. The upper tractor was then activated and pushed the tool string through the rat hole and down to TD of the section. Data acquisition was then performed while pulling out of the open hole. Length of the open hole section was 190 m.

Due to the prevailing weather conditions, the rig had to disconnect from the subsea template for 35 hours before the operation could resume. The need for a wiper trip was evaluated, but was considered unnecessary.

The second tool string, including density, neutron and pressure measurements, had a total length of 42 m. The string slid down through the rat hole and into the 8 1/2-in. section before the lower tractor was engaged. It pushed the toolstring to a point 50 m above TD, where a restriction was encountered. While attempting to log upwards from this point, the toolstring became stuck in the permeable Garn formation. It was not possible to conclude whether the cable or the tractors were stuck differentially. A 'cut-and-thread' operated was then initiated to fish the toolstring, which was accomplished successfully, followed by logging while fishing.

Pressure points could not be acquired due to a hydraulic leak in the MDT tool. The calliper log on the density tool revealed that the restriction was probably related to clay swelling in the Not formation. This restriction could be passed on TLC, but not on wireline using tractors. The electrical weak point was therefore used to disconnect the cable from the toolstring before pulling out of the hole. The MDT was then re-run on drill pipe to acquire pressures in the Garn and Ile formations.

Even though the second string got stuck and had to be fished, the operation proved that the tractor could be applied to wireline logging in high deviation open holes. As for conventional open hole wireline operations, it is important to focus strongly on optimum hole conditions. Currently a head tension measurement is not available using tractor on hepta cable. When this does become available, control of tractor versus speed will improve significantly.

The way to a successful operation is through planning in concert with the contractors. For this application, both Schlumberger and Welltec cooperated with thorough engineering and testing of the tandem tractor concept.