Richard Barrett, Graham Cheyne, Steve Molloy

Expro Group

The Malampaya deepwater gas-to-power (GTP) project represents the largest and most significant industrial investment in the history of the Philippines. The $4.5-billion project is expected to produce enough fuel to generate 2,700 Mw of power for 20 years – 30% of the Philippines' entire power generation requirements.

Project parameters

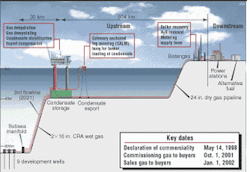

The project involves the development and construction of the Malampaya field facilities in 2,690 ft of water, a shallow water gas production platform 18.6 mi from the wellheads, a 313-mi subsea pipeline, gas-landing facilities in Batangas, and three power plants. If this wasn't challenging enough, the field lies more than 9,843 ft below sea level and is 49.7 mi. offshore northwest of Palawan. Five exploration and appraisal wells drilled by 1995 showed that it contains an estimated 2.6-3 tcf of gas.

Five subsea development wells were delivered through 2000 and 2001, and a manifold was installed at approximately 2,690-ft water depth and connected to the production platform via two 18.6-mi. flow lines. On the platform, dry gas is separated from condensate, which is transported to a catenary anchored leg mooring buoy and retrieved by tankers. The dry gas travels through a 313-mi, 24-in. carbon steel pipeline from the platform to a gas treatment plant in Batangas.

The players

Malampaya is a national flagship project of the Philippine government, the owner of the gas resource. Developers of the upstream component (the cost of which is valued at $2 billion) are Shell Philippines Exploration BV (SPEX), which holds 45%, along with joint venture partners Texaco Philippines, with 45%, and the Philippine National Oil Company Exploration Corp. with the remaining 10%.

In January 2000, an alliance of oilfield service companies including Expro Group Australia, BJ Services, and Baker Atlas, and led by project managers Expro Group Integrated Services, was awarded a major contract to supply well operations services for the five-well project. Within this contract, BJ and Baker would provide tubing-conveyed perforating, coiled tubing, pumping, and stimulation services. Expro would provide a suite of subsea and surface services, including permanent monitoring and subsea intervention, high rate clean-ups, and well testing services. From the outset of the contract work through to Expro's ongoing work on the project today, Malampaya represents a major commitment from Expro to a remote location, not only in terms of supplying equipment and personnel, but also in the depth of involvement throughout the planning and operational stages.

High rate clean-ups

Expro's clean-up of the five development wells was carried out early in the project schedule to avoid complicating flowline and platform start-up closer to the first gas milestones. The early timing would also be important to maintain the integrity of the subsea facilities systems, while providing clean gas for commissioning the topside facilities. Expro demonstrated that this strategy collected progressively better pressure volume temperature sampling analysis and accurate condensate-gas-ratio and water-gas-ratio data from well to well.

During well clean-up, condensate was separated from the gas using an Expro Megaflow Separator. Using high gravitational forces generated within the separator, liquid droplets are spun out of the gas stream and removed under level control to the downstream surge tanks or are sent directly to flare via the oil manifold. Use of the Megaflow meant that efficient separation could be achieved while minimizing the deck area required for the surface clean-up package.

Liquids were effectively burned at the flare using a Super Green Burner. A silencer on the gas flare tip helped to mitigate excessive noise experienced at rates of over 100 MMcf/d.

In November 2000, the GTP project required Expro's subsea team to complete the first five development wells using its first generation 7-in. subsea intervention landing string, a primary safety system for deployment of completions into horizontal wells, to interface with the horizontal christmas trees connecting to the subsea manifold.

All five wells were completed successfully with no incidents or accidents. Non-productive time was incurred on the first well only. Both Expro and SPEX personnel effectively overcame this through teamwork and problem analysis.

Further, Expro was able to establish a permanent subsea resource for the duration of the project in Manila, specifically to support this remote location project.

Oil rim possibilities

While the GTP project represented a major commercial opportunity, SPEX showed that an oil rim surrounded the gas field. As a result, one well was drilled to enable extended well testing (EWT) of the oil rim. In June 2001, Expro's subsea team was awarded a contract to deploy its second generation enhanced landing string assembly (ELSA) system into the well at the beginning of October 2001.

ELSA was specifically developed for use in harsh or aggressive well environments. Through discussions with SPEX on the design of the landing string and participating in various workshops held with Shell, Expro was able to re-qualify the tool to API 14A standards.

The project also proved the elastomer technology that Expro uses to an industry first 350°F (177°C).

The contract for the EWT topside facilities was awarded in April 2001. In keeping with SPEX's project schedule, equipment was mobilized onto the semisubmersible Atwood Falcon during October 2001. The floating storage unit, Stena Natalita, was hooked up during the last week of November, and the EWT started up in early December 2001 and lasted 150 days.

The well was flowed at 8,000 b/d, peaking at periods at up to 16,000 b/d for reservoir data purposes. After some acid stimulation work, production gradually increased to over 24,000 b/d (gas rate around 19 MMcf/d), which remained the steady flow rate during January 2002. On Jan. 28, 2002, the first shipment of 600,000 bbl of oil recovered during the EWT was transferred to an export tanker for delivery to a ChevronTexaco refinery in South Korea.

Since then, production from the Atwood Falcon has settled at a rate of approximately 23,000 b/d. A five-month EWT was executed as part of a program to appraise the Malampaya oil rim and gather data to establish whether a development of the Malampaya oil rim will be commercial long-term. At 2,690-ft water depth, the EWT is believed to be the world's deepest horizontal subsea well test.