OFFSHORE CANADA: Newfoundland solving gas transport, iceberg management challenges

Can a pipeline be laid on the Grand Banks' hard seafloor, an area replete with icebergs floating down from the north, to move Newfoundland gas and oil to market? Moving hydrocarbons through subsea pipe from fields offshore Canada's northeastern-most province presents challenges, but none that are insurmountable, according to engineers.

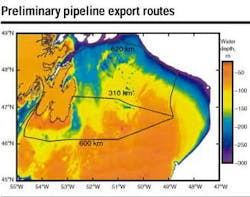

Project engineers have worked out three possible pipeline routes that could bring gas from the Jeanne d'Arc Basin in the Grand Banks west of Newfoundland into a pipeline system that would move it to a market that is actively in search of gas. According to engineering studies, safety and environmental considerations can be met for a gas pipeline on the Grand Banks through a combination of strategic routing and trenching.

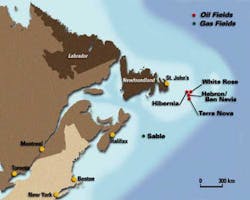

In addition to oil, west and southwest of Newfoundland is a highly prospective gas frontier, and the Canadian government has invested resources to find ways to exploit the province's reserves and transport them from offshore fields. Twelve million acres are under license offshore, and more acreage will almost certainly be added once the boundary dispute with Nova Scotia is resolved. Phase one of the arbitration process is completed, and there is optimism in both provinces that the dividing line will be established soon.

A recent call for bids announced details for the next round of bids for offshore parcels. The call will comprise 14 parcels totaling 1,969,664 hectares: three in the Flemish Pass, four in the Jeanne d'Arc Basin, three in the South Whale Basin, and four along the western coast of the province.

Prospective reserves

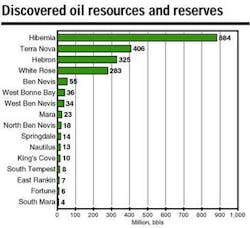

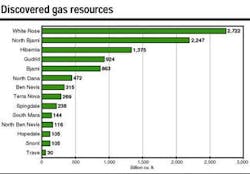

To date, 200 wells have been drilled offshore Newfoundland with a high rate of success. And some of those successes have been huge. There have been gas discoveries offshore Labrador, including the Bjarni and North Bjarni fields, which contain a total of 3.2 tcf of gas. And there have been tremendous finds in several fields in the Grand Banks, particularly in the Jeanne d'Arc Basin (Hibernia, Terra Nova, Hebron, and White Rose) where recoverable resources and reserves total 2.1 billion bbl of oil, 5.7 tcf of gas, and 309 million bbl of natural gas liquids (NGL).

Most of the discoveries so far have been in 80-100 meter water depths, which leaves a lot of prospective acreage untouched in the 700,000 square miles of offshore area, some in much deeper water.

With the sizeable discoveries of gas and oil offshore and the potential for finding much more, there is a need to find a market outside of Newfoundland. The province already meets its energy needs. The obvious markets for the reserves are mainland Canada and the US. But before those markets can be considered, a pipeline needs to be built. And that will only take place if a feasible route can be mapped and sufficient recoverable reserves are made available to make the pipeline profitable.

Iceberg gouging

The biggest physical impediments to moving gas and oil onshore to Newfoundland or to the southwest are climate and icebergs. C-Core, a St. John's, Newfoundland, consultancy specializing in ice engineering, geotechnical engineering, and harsh environments, was tasked with assessing the viability of constructing a pipeline from the Jeanne d'Arc Basin to landfall in Newfoundland. The company studied several pipeline routes, all of which pose the same primary challenge - avoid gouging by icebergs. Despite this, the C-Core report is promising.

On the Grand Banks, ice gouges tend to be shallow - typically less than 0.5 meter - but they occur in water depths up to about 200 meters. Occasional localized pits up to about 5 meters deep have been found. The deepest gouges were caused by ice impact that probably occurred when icebergs rolled or split. The potential for deep pits along a pipeline route is not a high risk to pipelines because they are rare events over a widespread area.

The most effective way to deal with ice gouges (and the most obvious) is to avoid areas where they are frequent. This objective has been achieved for one potential route which cuts northeast from the Jeanne d'Arc basin to deeper water north of the Grand Banks. Although gouges can be found in deepwater, they are relict features that have been preserved from a time when the sea level was much lower than it is today.

Ice management

Where present-day ice scour is occurring, the pipeline would have to be buried or armored with rock to resist being overstressed by a scour event. Through an extensive program of field studies, experimental modeling, and theoretical analysis, C-Core developed an engineering model that can be used to predict potential scour depths and stresses imposed on buried pipelines. The very strong soils that are typical of the Grand Banks seabed prevent the ice keels from gouging very deeply. On the downside, because of the high strength, excavation of the soils to the depth required to resist significant pipeline deformation will be difficult.

Another means of mitigating ice scour is by ice management. Icebergs can be detected by a variety of techniques, including aircraft surveillance, satellite monitoring groundwave radar, and marine radar. The potential for gouging can be determined from estimates of iceberg dimensions. If the potential for scour is high, an iceberg can be towed, or the draft of the keel can be reduced by inducing large pieces to break off.

The commercial feasibility of the pipeline eventually will be driven by the means by which ice scour is dealt with. The technical analysis indicates that it is feasible to construct a pipeline over any route deemed desirable without a risk that is any greater than in other regions where ice scour is not an issue.

Financial framework

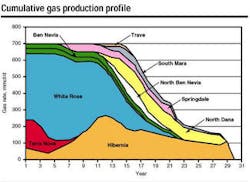

The government of Newfoundland and Labrador's Department of Mines and Energy has compiled data that indicate pipeline construction is not only a feasible prospect in the near future, but is a potentially profitable one. A techical feasibility study indicates that, based on throughput of present reserves in the Jeanne d'Arc Basin, a 36-in. line flowing about 700 MMcf/d over a life of 15 years is possible.

This flow scenario also assumes a pipeline completion date of 2015, which is a very conservative projection. There is a very good chance that construction could conclude five years earlier, which would place gas on the market in 2010.

A base-case production profile shows a scenario that takes into account only identified gas reserves produced using traditional means. Additional finds or the use of intelligent completion technology, which could expedite production, would increase the profitability and the productive life of the field. At least one pipeline company has already expressed interest in this project. If investment follows, the Jeanne d'Arc/Newfoundland pipeline could soon be the first subsea pipeline of its kind in the world.

Terra Nova going onstream this fall

The Terra Nova Field, located in 93 meters water depth in the Jeanne d'Arc Basin, is the second largest discovered oil development offshore Newfoundland. The field contains estimated recoverable reserves of 370 million bbl of oil, 270 bcf of natural gas, and 14 million barrels of NGL.

The Terra Nova floating production, storage, and offloading (FPSO) vessel, being built at Bull Arm, Newfoundland, is the first vessel of its kind in North America. Outfitted especially for work in the North Atlantic, the vessel is double hulled and ice reinforced to withstand the potential load imposed on it by icebergs of up to 100,000 tons.

The Terra Nova also can accommodate up to 2,000 tons of superstructure icing. The vessel contains the largest disconnectable riser system in the world. Weighing more than 4,000 tons with an overall height of 70 meters, Terra Nova's turret is the largest disconnectable turret mooring system ever built. Constructed to operate in the harsh North Atlantic environment to cope with hazards such as icebergs, it is composed of the upper turret, lower turret, and spider buoy.

When connected to the spider buoy, the turret is stationary. Specialized bearings allow the FPSO to rotate around the turret, so that the front of the vessel is always facing into the wind. In an emergency, the FPSO can disconnect in about 15 minutes, during which time, the spider buoy settles into a mid-water depth, ready to reconnect when the FPSO returns. The spider buoy - about 20 meters in diameter and weighing over 1,300 tons, supports nine anchor chains and up to 19 risers.

Production fluid path

The lower turret provides the connection with the spider buoy. The upper turret houses a collection of manifolds, hydraulic, and electrical control equipment, as well as the swivel stack, which serves as the interface between the subsea production system and the topsides processing and storage system. The swivels form a series of fluid flow paths which connect to piping on the FPSO itself. These swivels allow fluids or electrical signals to move back and forth from the subsea to the topsides while permitting the vessel to rotate around the turret.

Gary Bruce, Vice President of Petro-Canada Offshore Development & Operations, is optimistic about the technology being used in development of this field: "The knowledge and expertise we are developing through Terra Nova should help establish FPSO technology as a viable option for future developments on the Grand Banks and other harsh environments." The FPSO is nearly complete and is scheduled to begin working offshore in 3Q 2001.

All six wells required for startup have been successfully drilled in the northeast and southwest drill centers of the Terra Nova Field. Completion is underway on the last of these wells, all of the which have shown high flow rates. Eighteen more wells will be drilled over the 2001-2004 period, with additional drilling in the far east portion of the field next year.

Flexible risers and flowlines will transport produced fluids from the Terra Nova Field to the newly constructed FPSO. The first phase of hookup and commissioning is complete, and the vessel is undergoing sea trials. The final phase, deployment to Terra Nova Field in the Grand Banks, will take place once sea trials are favorably concluded.