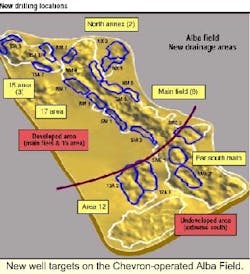

Advanced seismic processing has helped Chevron identify 70 million bbl of additional reserves on the Alba Field in the UK Central North Sea. Production constraints on the platform have been addressed through the use of novel slot sharing techniques, while productivity has also been improved through application of long distance gravel packing in horizontal wells.

Alba is a 400 million bbl heavy oilfield in the Central UK North Sea, first developed by Chevron and its partners in the early 1990s. The crude is processed on an eight leg, steel jacket platform in the north of the field, then piped 2.7 km to a dedicated floating storage unit for tanker offloading.

The reservoir is a poorly consolidated Eocene turbidite sand channel up to 100 meters thick in places. The oil lies beneath an upper cap of impermeable shales and is in turn underlain by a large volume of water. Horizontal wells were drilled from the outset to maximize recovery and minimize associated water production. The wells have been fitted with gravel packs and pre-packed screens to prevent sand entering the wellbores, with a calcium carbonate-containing mud employed to avoid obstruction to the pre-packed screen tubing. Downhole electric submersible pumps are also employed.

Initially, Chevron had planned to drill 20 development wells (15 producers and five injectors) under a first production phase development, with a second platform added later on to tap reserves in the south of the reservoir. However, subsequent advances in extended reach drilling persuaded the partners to drill these prospects from the existing platform. In preparation, gross fluids handling capacity was raised from 240,000 b/d to 390,000 b/d under a £267 million program, completed in December 1998.

Following the shales

Concurrently, Chevron was encountering problems caused by Alba's intra-reservoir shales. Paths of new wells needed to follow the reservoir's ceiling as closely as possible, which entails accurate mapping of both the ceiling and the shales. However, the imaging process was proving to be unsatisfactory.

Mapping had been based on seismic data acquired in 1989, but the process proved unsatisfactory, due to a weak, inconsistent seismic event at the top of the reservoir and also because the shales were seismically invisible. These uncertainties led to some of the newer wells encountering shale bodies and the reservoir top off-depth from the prognosed path. Also, there were anomalous water saturation profiles. In one well, water-wet sands were encountered above a sand with primary oil saturation. In another, partly oil-saturated sands were encountered below the original oil-water contact.

Chevron took remedial action early in 1998, mounting one of the world's first 4C (four component) ocean bottom cable seismic surveys on Alba. Results from this study were presented at last year's OTC.

The inconsistent seismic reflector at the top of the reservoir and the intra-reservoir shales had been attributed to similar acoustic impedance. Conversely, there had been a strong reflector at the oil-water contact caused by a P-velocity increase of 10%. Core measurements confirmed that this was also caused by a compressibility contrast between Alba oil and brine, and was not a diagenetic effect. A dipole sonic log revealed a significant contrast in shear wave velocity at the reservoir's top and bottom. This provided the basic rationale for obtaining an improved image of the reservoir using converted shear waves.

Seismic modeling was then employed in an attempt to improve understanding of the seismic response of the sand/shale interface and the oil-water contact. Models were constructed by populating the model space with velocities and densities using geostatic interpolation techniques. This ensured a heterogeneous impedance value distribution in each section of the model (oil leg, water leg, shales).

Data conversion

The results suggested that a clearer picture could be attained of reservoir and fluid movement by recording converted shear wave data, generating far-offset sections from the 1989 data, and also by recording a second streamer survey. OBC was the selected medium, using a recording system supplied by Geco-Prakla. The latter was also commissioned to acquire a 67 sq km, 3D multi-component survey in 14 km swaths parallel to the path of the1989 survey. Typically, this involved laying two 6-km cables, 400 meters apart, on the seabed, with 12 km long source lines shot parallel to the cables. Individual source line separation was 50 meters, with a maximum shot line-cable offset of 800 meters.

Both the 1989 streamer data and the P-wave OBC data were processed in tandem, using identical flows and parameters where possible. The converted wave data gave a markedly clearer image of the reservoir, which in turn aided interpretation of the top sand level and also identification of some of the larger intra-reservoir shales. Also, more visible were areas where the oil-water contact had been raised as well as spots where the seismic event had dropped 10 meters since 1989.

Drilling opportunities

As a result, Chevron was able to identify new drilling opportunities in Alba's northern section, all easily accessible from the platform. In particular, the shear wave data highlighted the flanking sand "wings" which were tested by three successful wells in 1999, at initial rates of 20,000 b/d. The challenge now was how to exploit these new reserves given the platform's limited slot availability.

Chevron and its partners had addressed this situation in 1995, installing larger diameter conductors in four of the drill slots to allow well "twinning." This technique was new to the North Sea, although it had been attempted in the milder conditions of the Gulf of Mexico before, with multiple wells drilled through single conductors.

Alba's pre-installed guides had been designed to accommodate 33-in. diameter conductors. Chevron decided that the best way to install larger diameter conductors for the new campaign (46-in.) would be to replace the guides. A design/installation project was initiated by the Alba subsurface team, in association with Brown & Root and Rockwater. The latter handled underwater installation work.

Preparations for the work included an integrity study of the Alba jacket to determine whether it could withstand the added conductor loads. That performance analysis was verified by Lloyds, which concluded that the jacket was still in good shape. Chevron also had to commission a Safety Case for having a diving vessel and platform supply vessel stationed alongside the platform for long periods.

A "cheese cutter" tool was developed - basically a continuous band saw designed for underwater operation. Work above the water line involved technicians abseiling down the platform to put in the large steel cross-haul structures. Operations started last November, in the North Sea's worst weather in 14 years, and were completed early this past April. Drilling wells through the shared slots currently is taking around 68 days on average.

The technique could be applied to other similarly constrained platforms, or to minimal unmanned platforms with low slot availability - although suitability may depend on the jacket's integrity.

Shale stabilization

Alba's latest six wells all feature long distance, open hole gravel packs. In certain cases, complete gravel placement has been achieved across horizontal intervals of up to 2,400 ft and 97 degrees inclination. However, the highly reactive Alba reservoir shale poses a threat of contamination to gravel pack completions. In response, the subsurface team developed a shale stabilization technique, which involves a solids-free base mud system being circulated over the open hole to maintain required stability.

Prior to gravel packing, a sodium-based brine system is circulated over the open hole. Laboratory-based shale stability tests have indicated superior inhibitive characteristics for the sodium brines, specifically for the Alba shale system.

Key completion objectives are to minimize screen plugging and to avoid inflow hotspots. The procedures emphasize cleanliness and through the use of solids-free systems, the potential for screen plugging is dramatically reduced, compared to previous standalone procedures.

Partial filter cake erosion is achieved via high velocity brine circulation. There is no requirement for acid or breaker treatments which may also create the potential for hotspots. All procedures aim to ensure that an even inflow profile is achieved along the entire screen section.

Production log data is acquired continually to verify that there are no inflow problems in the completion. The first log, run on the A25 well in 1999, confirmed even inflow into the wellbore. Data was acquired downhole using a wireline-deployed tractor. Based on the results, production from this well has been optimally adjusted, Chevron claims.