Amerada Hess' North Sea field, South Arne (SA), is being developed with horizontal wells and multiple hydraulic propped fractures. The South Arne field is located in the northern part of the Danish sector of the North Sea. The reservoir rock is high porosity (30-40%) and low permeability (1-2 md) chalk of Maastrichtian and Danian age, comprising the Tor and Ekofisk formations, respectively.

The direction of maximum horizontal stress is northwest to southeast. The first five wells were drilled in this general direction with the exception of the first (Well A) which was drilled northeast to southwest. Virgin reservoir pressure is 6300-6400 psig and the reservoir temperature is 240 degrees F.

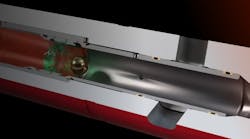

The completion method selected for the five batch completed wells allows each individual (stimulated) zone to be mechanically isolated from the rest. While stimulating, the annulus between the work string and the liner is open, facilitating a live annulus. This provided excellent control during treatments since BHTP was monitored close to the perforation for all the jobs.

Production engineering

The primary objective for hydraulic propped fracturing of the five producers was to ensure a plateau production of 50,000 b/d of oil as soon as possible, and for as long as possible. All five wells have now been on production for 6-12 months, where total production is at, or above, expectation (~50,000 b/d of oil). As part of the data gathering strategy on South Arne, coiled tubing PLTs are run immediately after an initial clean up period. Conclusions from the PLTs are that all zones are open and flowing, and that the productivity of each zone is related to zonal porosity.

The fluids utilized for the SA fracturing treatments were borate crosslinked and freshwater based. To obtain a satisfactory crosslinking of the fluid and to ensure a stable fluid for the duration of the treatment, it was decided to enter the campaign with an HPG-based fluid system. Initial analysis revealed that expected regained permeability would be moderately low if a seawater-based system was used and the program was consequently based upon the use of a freshwater system.

Based on fluid test results, a 40-lb Guar based and a 35-lb HPG based fluid were proposed. Optional (and very stable) 50-lb Guar fluid and a 40-lb HPG fluid were also developed. Total pumping time for a typical treatment of 600,000 lb would be 75 minutes. Once a stable fluid formulation had been agreed, break testing was conducted on these parameters.

The test results indicated that it was beneficial to ramp up the high-temperature breaker concentration from 2 gals/Mgals to 6 gals/Mgals, while decreasing the polymer loading from 40 lb to 30 lb, and decreasing the initial (surface) crosslinked fluid pH from 11.5 to 10.0. This change was made at the start of the TSO (tip screen-out).

Fluid testing also revealed the relationship between pH and leak-off. Apparently, the pH for this particular borate system has much more impact on the fluid efficiency than gel loading. This again impacts the perceived fluid damage caused by the specific amount of gel pumped.

Conductivity and proppant

The choice of proppant was driven by a design requirement for a minimum dimensionless fracture conductivity (Fcd) value of 10, as:

- Each transverse fracture has a radial convergent skin effect that must be compensated for

- The high water saturation in the fracture reduces the fracture conductivity near the wellbore resulting in an effect similar to convergent skin

- The broken fluid will reduce the proppant conductivity by a minimum of 50%

- Multiphase flow effect increases deltaP inside the fracture with increasing gas-oil ratio (GOR)

- Uncertain fracture dimensions (width)

- Embedment reduces effective proppant concentration

- Fines migration (of soft chalk into proppant pack).

Testing revealed that 16/30-mesh sand should be used to cater for these uncertainties.

Batch stimulation

The operational objectives for the treatments were specified during the batch-completion campaign:

- Obtain TSO in every treatment with areal proppant concentrations in excess of 6 lb/sq ft

- Place at least 90% of designed proppant volume

- Cover at least 75% of the Ekofisk formation in situ

- Tail-in with a minimum of 50,000 lb resin-coated proppant

- Avoid wellbore screen-outs.

A live annulus well configuration was used for all treatments. As the casing is not designed to withstand the pressures exerted during screen-out, this technique requires the use of an annular safety system. However, there are significant advantages to using this system:

- It allows instantaneous changes in friction and net-pressure to be monitored and thus provides the control required for effective TSO-design.

- Crosslinked gel can be circulated to the perforations, and by including 100-mesh sand in this string displacement, it is pumped at the earliest possible stage of the treatment. As presented earlier, it is strongly felt that the early addition of 100-mesh sand reduces the chances of multiple fractures forming and is thus a major factor in treatment success.

A typical treatment consisted of string displacement, injection test/minifrac, main treatment and finally weighted brine flush.

Treatment response

The injection tests are normally displaced with linear gel. From experience gained through the campaign, it appears as if linear gel should be avoided when porosity is low. This has caused a general change in design, so that on the low porous zones, it is recommended to avoid the injection test, or at least to displace the injection test with partly crosslinked gel.

The reason for the apparently detrimental effect of low viscosity fluid in low-porous chalk is probably best explained by an increased risk of creating multiple fractures when the Young's modulus (as a direct function of porosity ) passes a certain magnitude. This is particularly so when initiating (or re-initiating) the treatment with a low-viscosity fluid. This explanation is partly supported by observed differences in re-initiation pressures between high-porosity and low-porosity zones. Also, proppant entry pressures seem to indicate little fracture width and tortuosity in treatments where porosity is less than 25%.

It is conceivable that supercharging will change the near wellbore stress matrix, whereby the natural preference for fracture initiation may change. With uni-directional perforations, this would equally start uni-directional fractures, and the proppant would meet significant friction in the tunnels as the varying width generated by the equivalent net pressure is distributed across potentially all perforations. Generally, the strategy for initiation follows the perceived ability to build net pressure, as described by:

Pnet~E'(mQL)1/4 HThis simplified relationship favors a high viscosity as well as a high pump rate for building net pressure, even though the exponent reduces the significance of change. For the initiation, it is important that the fracture system stays as simple as possible, to generate a fracture wide enough for proppant entry. One hundred mesh sand has been used as a primary means of simplifying the geometry and reducing leakoff.

The use of 100-mesh sand has been widely debated, although the only explanation of its effect relates to its ability to change the apparent leak-off (it may be observed that 100-mesh sand on occasion changes fluid characteristics; if the viscosity is greatly changed, the efficiency may also change, further impacting ability to leak off).

Every treatment in SA wells has been initiated using crosslinked fluid with 1-4 ppg 100-mesh sand. In most cases, the main treatment pad also contained a 1-4 ppg 100-mesh sand slug. It is felt that this design has been instrumental in simplifying fracture geometry, and hence reducing bottomhole treatment pressures prior to proppant entry. The explanation offered to this is that minor fractures taking fluid during the initiation phase will easily be plugged by 100-mesh sand-laden crosslinked gel. Once initiating the main treatment with linear gel, the commonly used 100-mesh slug in the pad is seen as a means of curing multiple fractures potentially created by this fluid.

The concentration of the 100-mesh sand appears to be very important. Less than 3 ppg is rarely seen as having any effect, while 4 ppg and above (in certain cases) generated large pressure increase upon entry. It should be considered that screening out with 100-mesh sand at the perforations could make treatment re-start very difficult, and sometimes impossible. The effect of 100-mesh sand has not been to uniformly decrease pressures, and on occasions it actually caused a slight increase in bottomhole treating pressure. This has been interpreted as the fluid temporarily stopping the fracture(s) from extending, building width, and then "letting go" as the pressure increased beyond that required for further propagation.

Overall stimulation results

During the batch completion of the five SA wells, a total of 66 propped fractures were executed in the field leaving 50 MMlb proppant in the ground, averaging 800 Klb per zone. This includes four premature screenouts and three frac-pack treatments. Frac-packs were carried out when either a premature screenout or a mechanical failure ended the original treatment prematurely. The bottom hole pressure response during the frac-packs suggested that proppant was entering the original fracture.

The table shows the general campaign results including history matched (minimum) areal coverage. If the rock mechanic measurements and fracture modeling assumptions are correct, it can be concluded that the design criteria in general were met for the batch stimulation campaign. This is certainly supported by the production results.

- The live annulus concept allows the operational advantage of being able to circulate high viscous fluid almost to the perforations.

- Reducing the pH in a borate fluid system increases the fluid efficiency but decreases fluid stability.

- Cool-down effects must be taken into consideration when testing fluid stability in order to optimize the fluid system.

- At the given reservoir conditions, a Guar-based fluid system will provide the same regained fracture conductivity as an HPG-based fluid system.

- For horizontal wells in chalk reservoirs it is recommended to initiate a fracture with a high viscous fluid and a high pump rate.

- Low viscous fluids appear to increase near wellbore fracture complexity.

- One hundred mesh sand slugs in the fracture initiation phase has proved to reduce excessive leak-off and simplify the fracture geometry.

Conclusions

In general, it can be concluded that the stimulation design criterias for the five SA wells were met, which is also supported by the production results.