Combined cycle plant to power Snorre production platforms

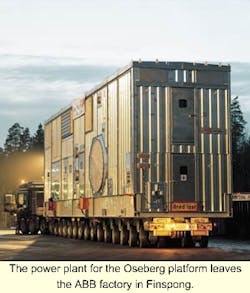

A steam turbine for a combined cycle plant left the ABB Alstom Power factory in Finspang, Sweden in March on the first part of its journey to the Norwegian North Sea. At 190 tons, the unit was the largest load ever to leave the factory and consisted of a steam turbine generator set with its auxiliary systems and mains condenser mounted on one common skid. The 17.3 MW steam turbine power plant traveled as a single unit slowly by road on the first part of its journey for installation on the Snorre B platform.

When it is in operation offshore, the high output of the unit will also enable it to provide the Snorre TLP with its surplus power. The unit was dispatched fully assembled in a single lift container that requires only the connection of inlet/extraction steam and cooling water system piping and high voltage cables at skid edge for it to be ready for operation.

The steam turbine unit has been designed to withstand 27° of accidental heel without damage and it has been fitted with higher specification soundproofing. This has been designed to limit noise output to 75 dB, rather than the 85 dB which is common elsewhere.

Heat recovery

The heat recovery steam generator (HRSG), which is the other part of the contract, has been designed and supplied by ABB Alstom Power Environmental in Oslo. This HRSG is designed for offshore use and is therefore light and compact. The combined cycle application used for Snorre B provides increased efficiency and has established new benchmarks for the performance of power generators. This is achieved by using the exhaust heat from the gas turbines to generate steam in a boiler. The steam is then used to drive a steam turbine. By making optimum use of the fuel consumed, the combined cycle plant operates with the exceptionally high efficiency level of 51% (compared with 30% for a normal gas turbine power plant).

This efficiency is particularly valuable for platform operators in the Norwegian sector of the North Sea where the country's carbon dioxide tax provides a powerful incentive for operators to become more energy efficient. The use of more efficient methods of power generation can make a major contribution towards what can become a high tax burden.

A typical offshore power plant generating 20 MW of electricity can cost its operator NKr 25-30 million in taxes every year. Since the tax is related to the fuel consumed, there is a very real advantage to be gained from improving power generation efficiency. ABB Alstom Power claims that the use of its combined cycle generating system can result in a 25% saving in fuel with a corresponding reduction in the operator's tax bill.

The Norwegian levy has few enthusiasts among offshore operators, but Bo Svensson, Marketing Manager, notes that it does serve its purpose. "The tax gives the operators the incentive to look for more efficient ways of producing energy." It gave his company the motivation it needed to develop its combined cycle offshore power generation system and ABB Alstom steam turbine plants can now be found on three Nor wegian platforms - Oseberg, Eldfisk and Snorre B.

The payback period required for an offshore combined cycle tailing costing NKr 100 million will depend both on any tax obligation and also on the value that the operator places on the fuel being burned. The payback time is typically estimated as being between two to three years. ABB Alstom feels that the greater energy efficiency of the combined cycle should also make the system attractive for other regions and applications, such as large ships or anywhere where the cost of fuel necessitates careful consumption.

Alwyn North

The company recently an nounced a contract to supply a GT35 gas turbine generating set to TotalFina for installation on the Alwyn North platform in the UK sector of the North Sea. The skid-mounted unit will comprise a GT35 gas turbine, rated 17 MW (ISO) an electric generator and auxiliary systems. The gas turbine will be fueled by natural gas with diesel oil used as a backup.

The Alwyn North platform is located 100 miles east of Shetland and has been operating since 1987. It is equipped with three generating sets of a similar size based on aero-derivative gas turbines. Power is also exported to the TotalFina-operated Dunbar platform which came onstream in 1994. The GT 35 generating set will operate in parallel with the others to meet demand for additional power on both platforms, principally for gas compression and water injection. The contract was awarded following an evaluation of life-cycle costs, including maintenance and operation. The long periods possible between overhauls of the GT35 turbine and its relatively high efficiency were important factors in the choice.

The flexible design of the GT35 was also seen as a benefit, as it allows what would normally be a single lift set to be supplied in packages each weighing less than 35 tons. This makes it possible for the power plant to be installed by the platform's own crane and to avoid the expense of a heavy lift barge. In addition, ABB Alstom is able to meet the relatively short time table for delivery so that the operator can use the platform crane during favorable weather conditions. Installation on the top deck of the platform is scheduled for the end of this summer.

The GT35 is a lightweight gas turbine of the heavy duty industrial type. In open-cycle operation, it has the relatively high efficiency level of 32% (ISO). There are currently 15 GT35 units installed on offshore platforms around the world both in power generation and mechanical drive applications. Three sets installed in 1985 on the Ula platform in the Norwegian sector of the North Sea have now operated for 80,000 hours each with 98% availability, and after 40,000 hours, they registered power degradation rates of less than 2%.

For more information contact Inger Welander, ABB Alstom Power, Tel: +46 122 810 00, Fax: +46 122 165 80. E-mail: inger.welander @se.abb.com