The traditional blowout preventer (BOP) stack has not experienced much change or innovation through the years. The few changes made have been in elastomers and sealing mechanism technologies.

Unique innovations, however, are starting to emerge in BOP technologies. Shaffer has introduced boltless BOP doors, automated ram changing systems, a weldless-cavity enhanced ram locking system, and a floating ram block design, to name a few.

Boltless BOP doors yield benefits such as reduced weight, reduced height, elimination of hands-on manual labor (a key health and safety issue), elimination of cross threaded bolts, and ram change time reduced from four hours to 40 minutes (15 minutes with an automatic ram changer).

The ram locking mechanism within the piston assembly is enhanced with the Shaffer UltraLocktrademark II system. This locking system is not dependent on closing pressure to maintain a positive lock. The system automatically locks in the closed position each time the piston assembly closes.

The system requires no adjustments for varying pipe size. Only one hydraulic function is required when operating the cylinders' open/close function. Maximum hang-off weight is 600,000 lb at full working pressure.

Ram changeout

One of the newest innovations in routine BOP operations is the use of a mechanical ram changing arm. The automated ram changer (A.R.C.trademark) effectively removes personnel from the ram changing operation. The absence of bolts on the Schaffer ram doors creates an immediate time-savings. Traditional ram door bolts can require up to 15 minutes for removal, 30 minutes to clean and prepare threads, and 35 minutes to re-install the bolts. Total change time required can be 30% of a traditional BOP ram design.

Transporting BOP stacks can require multiple equipment loads to the dock for delivery to the offshore platform. The stack arrives at the rig or platform unassembled requiring complete nipple-up. This is efficient and requires valuable rig time to complete. All ram wear components are removable, implying infield repairs are possible now.

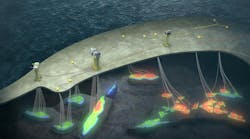

The next step for this technology will be taking it to the subsea environment. The ability to change rams without having to pull the BOP stack will result in time-savings. For operations in deep and ultradeep waters, this will contribute directly to the bottom line.

Rotating BOPs

Rotating BOPs are not new to the industry. They have been used for years in different capacities and applications around the world. Most of the work with rotating BOPs has been done on land, with limited use in the offshore environment. Common industry thinking is that rotating BOPs are only useful for under balanced drilling (UBD) applications.

The BOP senses well bore pressure and adjusts annular rubber pressure to a preset differential over kick pressure. One operator currently uses the Schaffer rotating BOP to rotate in the prevention of stuck pipe.