How collaboration worked on the Triton development

Triton, a fast-track, three-field project due onstream in November, has been cited by UK Energy Minister John Battle as highlighting his belief that collaboration is vital for the future success of the UK offshore industry. Indeed, it is claimed by the fields' operators that "cooperative working on Triton is a benchmark and model for future development in the UKCS."

The sanctioned development cost is £540 million and the project will come in within that figure. Average annual operating cost, including tariffs, will be £36 million a year. Six companies, Amerada Hess, Shell, and Veba Oil & Gas, together with partners Esso, Enterprise, and Paladin Resources, have combined their expertise to develop the Bittern, Guillemot West, and Guillemot North West fields, 190 km southeast of Aberdeen.

This team approach, involving the sharing of an FPSO, enabled the earliest possible development of the fields - three years from the Bittern discovery in 1996.

But, for almost a year, it was confrontation rather than collaboration. Originally, there were two names for the main discovery, which straddles two adjacent blocks - 29/1b (Amerada) and 29/1a (Shell). They had shared the cost of drilling three wells, but Amerada designated it Abbot, while Shell knew it as Razorbill. Two names, and also two differing development ideas, not to mention bitter arguments over operatorship.

As a pioneer in the use of floating production systems, Amerada went ahead and invited bids for a floating production, storage, and offloading (FPSO) vessel, while Shell planned a subsea tieback to a new bridge-linked platform on its Gannet fields. Meanwhile, Texaco, then operator on Guillemot West, mulled a stand-alone development with a floater.

After much wrangling, agreement was reached in March 1997 between Amerada and Shell to use an FPSO, and by November that year, when they had agreed to rename the fields collectively as Bittern, Texaco had joined the development.

Joining activities

Amerada's John Moseley, the Triton project manager, says "Once the issue was resolved, we have had nothing but the strongest input and support from Shell." Amerada leads the combined project team, and is responsible for the jointly owned FPSO, which it will operate and will also carry out day-to-day operations of the subsea facilities.

Bittern, with recoverable reserves of 108 million bbl of oil and 116 bcf of gas, consists of a Rogaland/Forties reservoir with an oil column, partially overlain by a gas cap. An aquifer is attached to the oil-bearing interval. The field is normally pressured. Field life is put at 11 years. Shell is operator and leads the subsurface team.

Guillemot West lies in blocks 21/29a (Veba-operated) and 21/25,21/30 and 21/29b (Shell) in 87 meters water depth, while North West is in Block 21/24 (Veba). The fields, with a life of 10 years, are a cluster of separate oil and gas accumulations in sandstone reservoirs. Total recoverable reserves are 30 million bbl of oil and 138 bcf of gas.

Texaco, which had been responsible for drilling and leading the subsurface team for Guillemot, sold its interests to Deminex in July, 1998. When the Deminex joint venture was split up almost immediately afterwards, Veba took on the UK assets. Shell now leads the subsurface team until the end of the development phase. Veba will then assume operatorship, its first in the UKCS.

Bittern, Guillemot

Drilling of all the wells, which are scheduled for completion before first production, is being carried out by a joint Shell/Veba team. On Bittern there will be four deviated producers and two water injectors. On Guillemot West there will be three horizontal producers and one gas producer, with one horizontal oil producer on Guillemot North West.

The collaboration has been much wider than between the operators and their partners, Moseley says. "The FPSO is far more sophisticated than anything we have built before. Valuable information has been given by other operators of FPSOs. Experts in various disciplines around the world have also contributed their knowledge in such areas as metallurgy and compressors."

"We adopted a fast-track approach and parallel engineering was carried out while the reservoirs were still being appraised. Functional specifications were used by contractors, but we laid down certain parameters which we had learnt from our own operating experience. When in doubt we took a conservative route."

FPSO design

On August 28,1997, Kværner was awarded a $338 million contract by Amerada for the design and construction of the FPSO. A 224-meter-long, 105,000-dwt Aframax double-hulled tanker, under construction at Samsung Heavy Industries in South Korea, was acquired and the hull converted into a production ship.

It was moved to the Sembawang yard in Singapore where, between August and November, 1998, further strengthening around the moonpool and turret area was carried out and the moonpool casing installed. The vessel then sailed under its own power to the Tees Offshore Base, where it arrived on December 6. The engines were removed and mothballed.

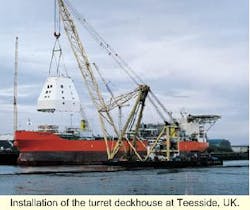

Some 7,500 tons of process and utilities equipment were installed and commissioned by the workforce from Kværner's Port Clarence fabrication facility where the process topsides were assembled. The mooring system, using an internal bow turret, 4.4-meters diameter, has been designed by Bluewater. There are 3 by 3 lines, each 1250 meters long in a chain/wire/chain system. The turret was fabricated by Lewis Offshore.

The vessel is now expected to be towed out to the field in the autumn by Stolt Comex Seaway, which will perform offshore hookup. It will be located in block 21/30, 20 km to the northwest of Bittern and 10 km to the southeast of the Guillemot fields. It has storage capacity for 630,000 bbl of oil (six days peak production). The process facilities are designed to handle 105,000 b/d of oil, 140 MMcfd of gas, and inject 125,000 b/d of water into Bittern.

There are nine Coflexip flexible risers and two umbilicals. Fifteen riser slots have been installed, allowing for additional risers to be added. After two years production, there will be spare capacity to handle production from other fields. Amerada has a prospect in the area as does Shell in Block 21/30, while Veba has Clapham in Block 21/24.

First oil in November

First oil production is now scheduled for November. At one time a target date of May had been set. "The topsides turned out to be heavier than we thought", said Moseley. "We under-estimated the complexity and the weight. There was a 1,500 tons increase, mainly due to the compressors." Now first oil will be out some two to three months beyond the revised date. Gas production will follow two months later.

Offshore loading for the oil is from the stern of the FPSO. Each partner will nominate its own shuttle tanker. Gas will be exported via a 10-in., 12 km spur line from the FPSO to the Fulmar gas trunk line, where a new pipeline end manifold has been installed.

Subsea

Stolt Comex Seaway was awarded the subsea facilities contract on December 24, 1998, with the main subcontracts to:

- Andrew Palmer and Associates (pipeline and overall system design)

- Allseas (Guillemot West and gas export pipelines)

- MacGregor Energy Services (manifolds) and Duco (seabed umbilicals).

The main features are nine pipelines, totaling more than 160 km in length; six subsea structures - four production manifolds, an SSIV skid, and a pipeline end manifold; two control/chemical umbilicals totaling 40 km in length and an electro-hydraulic control system.

One of the main challenges was the relatively long tieback distances of the fields to the FPSO -22 km for Bittern and 10 km for Guillemot - and the need to prevent wax depositioning in the pipelines as the oil cools on its journey to the FPSO. To prevent a buildup of wax, particularly on Guillemot West, where the temperature of the oil at the wellhead is only 55°C, pipe-in-pipe insulation will keep the oil above 34°C- the point at which wax forms. Permanent round-trip pigging facilities are available. All the subsea work, apart from the tie-ins to the FPSO, has been completed.