Deepwater pipeline repair beyond saturation diving depth has been recognized as a formidable industry challenge. Mariner Energy faced this challenge recently when leaks were discovered in two high-pressure 4.5-in. flowlines just before they were to begin exporting gas from the company's Dulcimer subsea development project.

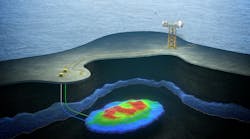

Dulcimer is a single subsea well on Garden Banks 367 in 1,187 ft of water, tied back 14 miles to the host platform on Garden Banks 236. A hole had been ground into each flowline and the umbilical had been damaged at a distance of three miles from the well in 996-ft water depths. It is believed the damage was caused when another operator's flowline was dragged across the Dulcimer lines during a bottom-tow installation.

Mariner Energy owns a 42% working interest in Garden Banks 367 and is the operator with Spinnaker Exploration Company, 33% and Pogo Producing Company, 25% working interest.

Evaluation of damage

The damage was discovered when pressuring up the flowlines to commission the subsea systems from the host platform. The lines would not hold pressure and bled back to 500 psi, indicating the leaks were in approximately 1,000-ft water depth. A DSV was immediately mobilized to investigate. A small ROV-operated dredge cleared soft soil from around the damaged areas, revealing oval-shaped holes 4 in. long by 2 in. wide in the flowlines. The umbilical showed similar damage down to the second layer of steel protection wires.

Mariner Energy is believed to be by far the smallest exploration and production company operating field developments in deepwater. Small companies operating in deepwater face challenges of access to technology and managing the huge risk costs associated with drilling and development projects.

Mariner has mitigated many of these risks through a very close commercial and technical relationship with Oceaneering International.

A team from Oceaneering was mobilized to Mariner's offices shortly after discovery of the problem. With 60-MMcf/d gas capacity, this well was important to the company's yearly revenue, and thus speed of repair was critical.

The normal repair method would have been to pick up the damaged lines with a pipelay vessel, but the cost and weather risks of this type of repair in late winter were extreme. Oceaneering believed the flowlines could be repaired on bottom, even though such a repair had not been attempted before in this water depth. Oceaneering offered to turnkey the work and guarantee the repairs for one year, which for such a difficult operation persuaded Mariner to give Oceaneering the go-ahead. Oceaneering's multi-service vessel (MSV) Ocean Intervention immediately returned to the damaged lines to make measurements and prepare the lines for repair.

Repair options

The team reviewed repair options over a 3-day period, considering the advantages and disadvantages of five major scenarios:

- Option 1 - On bottom repair using Oceaneering's Smart Flange Plus connector.

- Option 2 - On bottom repair using a modified Hydro-Tech hot-tap clamp.

- Option 3 - Retrieve the flowlines to the surface, cut out the damaged sections, install conventional flanges, lay down, and install spoolpieces on bottom with an ADS and ROV.

- Option 4 - Back-spool the flowlines, cut out the damaged sections, weld the flowlines on the deck of the reel/lay barges, and relay the flowlines to the subsea tree.

- Option 5 - Pick up the flowlines at the damage area, cut out the damaged sections, and weld on spoolpieces at the surface.

Option 2, installing clamps over the damaged sections, was considered to be the easiest on-bottom repair. Critical pipe roundness measurements found the flowlines to be mechanically suitable for a clamp repair. However, Option 2 was dismissed for four major reasons:

- Clamps of this pressure rating at this diameter had not previously been manufactured.

- Small cracks found in the damaged area might grow.

- The inside of the damaged area might not have allowed pigs to pass

- Most importantly, Oceaneering would not warrant the method because the company does not manufacture clamp repair systems.

Option 3 was ruled out because of time. No suitable barges were available and the additional pipe required had to be manufactured. The dependence on good weather for this type of work would cause a delay of 60 days to get into a summer pattern.

Option 4, the pick-up and relay method, had been used successfully to repair pipeline buckles, but this option was ruled out for the Dulcimer application due to:

- The complications of pipelay vessel availability

- The time and difficulty of disconnecting the flowline skid from the subsea tree

- Potential problems associated with reeling the dual flowlines back to the damaged section and then relaying and hooking the line back up.

Option 5 also suffered from the lack of suitable barges and weather dependency.

Selected system

Mariner concluded its intensive review of options by selecting on-bottom repair using the Smart Flange Plus connector system manufactured by Oceaneering. The connector is a sleeve-type mechanical connector for in-line spoolpiece pipeline repairs that slides over the end(s) to be joined.

When bolted to a standard ASME/ANSI flange, the tightening of the bolts compresses a piston into the connector body, energizing a slip and cone mechanism which sets and locks the connector to the pipe. At the same time, this action compresses an elastomeric element to provide the necessary seal. The connector is thus set, locked and sealed in a single bolt-tensioning operation. The connector is designed for easy diver-assisted installation and, as demonstrated here, is readily adaptable for diverless requirements.

Installation challenges

Major challenges presented by the Dulcimer repair included the following:

- Schedule: The schedule was an urgent matter with revenue being lost every day that production remained shut in. The repair was planned and performed on an extreme fast-track basis.

- Water depth: At a depth of 1,000 ft, the damaged flowlines were at the extreme limits of saturation diving, which also would have been very costly. An Oceaneering WASP atmospheric diving system (ADS) working together with a remotely operated vehicle (ROV) was determined to provide the best solution. This decision raised another difficulty, however. Neither ADS nor ROVs can work effectively on the seabed. Their thrusters stir up sediments, reducing or totally obscuring visibility. It was thus necessary to raise the flowlines a few feet above the seafloor.

- Removal of the fusion-bonded epoxy: It was also necessary to remove the fusion-bonded epoxy coating on the flowline ends to accommodate the Smart Flange connectors because of the tight tolerances required to ensure integrity. A specialized coating removal tool was built to perform this task.

- Preparation of the flowline ends after cutting: The flowline ends had to be cleaned to remove burrs that might cause seal damage within the Smart Flange sleeve. A tool was adapted to this purpose.

- Alignment of the flow-line ends: Alignment of the flowlines was critical to ensure that the Smart Flange Connector would properly fit and achieve its full pressure test rating. Alignment had to be made prior to spool insertion.

- Weather: Late winter weather conditions during March and April posed a stationkeeping challenge for the surface support vessel. The newbuild MSV Ocean Intervention, with its state-of-the-art Simrad SDP-21 (DP-2) dynamic positioning system, two 1,000-hp bow tunnel thrusters and two 2,000-hp azimuthing stern thrusters is designed to hold station in any weather conditions short of a named storm. The MSV is also equipped with a resident 150-hp ROV system that can be launched and recovered through a dedicated moonpool in any weather that the vessel can hold station. The availability of this MSV for the Dulcimer repair allowed Oceaneering to assume the risk of weather downtime in the turnkey contract price.

- Special tools: Special tools needed for repair Option 1 had to be built and tested prior to going offshore.

All of the diverless equipment and specialized tooling, as well as the entire flowline repair procedure, were tested over a five-day period in Oceaneering's wet tank in Morgan City, Louisiana prior to mobilization of the repair spread. Lessons learned from the wet-tank testing proved invaluable during offshore operations.

Problems arose with the offshore installation work only when it was necessary to depart from the procedures practiced in the tank. Even with the small problems which arose during the repairs, all the work was performed within the budget and schedule requirements set forth in the contract.

Offshore operations

The flowline repair equipment and personnel were mobilized at Fourchon, Louisiana on March 25th, six days after award of contract. The MSV sailed to GB-323 and performed survey calibrations and DP trials prior to beginning the repair operations.

After the damaged area of each flowline was inspected and photographed, an A-Frame was overboarded, lowered, and positioned over the damaged section of pipe. The flowlines were raised out of the mud by chain falls, and the WACHs guillotine saw made the first pipeline cut.

Six adjustable pipe stands were placed on the seabed at predetermined distances adjacent to the flowlines, and the flowlines were lifted onto the pipe stands and aligned with each other using the adjustment capability of the pipe stands as well as subsea alignment rigging.

An angle iron measurement/alignment jig was utilized to confirm accurate alignment and to measure and mark the pipe prior to cutting out the damaged sections of pipe. The pipe ends were prepped with the milling tool and 16 in. of the FBE coating were removed from the pipe ends with the coating removal tool.

One connector was slipped onto the south end of each of the flowlines. The two 10-ft long pre-fabricated spool pieces were rigged up with the connectors attached to the weld neck flange on one end, lowered into position, and slipped over the north ends of the flowlines. Then the weld neck flanges on the south end of the spool pieces were bolted to the connectors on the flowlines. The bolts on both ends of the spool pieces were tensioned by hydraulic impact and hydraulic torque wrenches, setting, locking and sealing the connectors.

The repaired flowlines were lifted off the pipe stands and replaced on the seabed prior to pigging and hydrotesting. The A-Frame, pipe stands, and alignment rigging were recovered to the surface. The repaired lines were hydro tested to 7,800 psi for 8 hours. The repair spools were then subjected to a gas test at maximum SITP prior to flowing the well.

Conclusions

The on-bottom repair was a success in large measure because the correct equipment and people were brought together to implement a well thought-out procedure. In-tank testing of procedures and equipment, use of an ADS and ROV to work together, an MSV that could handle the weather during the repairs, a seasoned repair team, and the strong working relationship between operator and contractor, all contributed to the success of the repair.

Due to its robust design, the umbilical did not need to be repaired. The Dulcimer well was shut in for just five weeks, and the offshore repair operations were performed in seven days. Although ADS were used for some of the underwater work, the equipment and procedures employed can be readily adapted for ROV installation, extending the use of this technology to water depths of 10,000 ft for small diameter lines.

The Authors

Dave Huber is Director, Deepwater Developments, for Mariner Energy, Inc., and one of the founders and principals of the company. Previous to Mariner, he held management positions in Aberdeen and London for Hamilton Oil and managed subsea projects in the Gulf of Mexico for Mariner's predecessor, Hardy Oil & Gas. He started his career with Exxon's Deepwater Drilling Group.

Richard Weser is the Manager of Subsea Systems for Mariner Energy with responsibility for new project development, system operability and interventions. Prior to joining Mariner, he held operations and supervisory positions with Tatham and Tenneco. He began his career in the offshore production engineering group of Amoco.

Norb Gorman is Manager of Oilfield Projects for Oceaneering International, Inc., responsible for contracting, planning and executing major turnkey subsea workscopes, often on lump-sum terms. He began his career as a diver, advanced into project management, and has accumulated 25 years of experience providing underwater installation, construction, and intervention services to the offshore oil and gas industry.