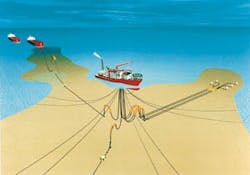

Artist's impression of the Banff oilfield development.Three vessels for a marginal field may lack a certain ring of logic, but that is the solution Conoco UK has chosen for its Banff oilfield development, basing production around a tried and trusted seismic ship.

Conoco can hardly be accused now of being a boring, me-too operator, but this exercise is more than an image-lift. The economics of Banff derive from its flexibility, with facilities designed to come and go during peaks and troughs of production, avoiding disproportionate excess capacity towards the end of the field's life.

Banff was discovered in 1991, lying mainly in UK block 29/2a, also extending into Ranger's block 22/27a. Three subsequent appraisal wells all flowed at a reasonable rate, yet at the same time confirmed the complex geology. This is a steeply dipping and heavily faulted Upper Cretaceous reservoir, with a 3,000 ft oil column, situated around a salt diapir piercement and beneath Paleocene sands. BP's Machar Field 20 miles east has similar characteristics.

Machar underwent an extended production test prior to integration in the ETAP development, and a similar course was mapped for Banff. Phase 1 production from the field began last September with a six-month extended well test. Semisubmersible rig Sedco 707 was upgraded to handle production at 35-40,000b/d, offloading to the DP tanker Stena Savonita.

This exercise generated 5MMbbl, but more importantly, according to Banff project manager Iain MacMillan, "The data acquisition was very successful, a lot of questions were answered and uncertainties were eliminated. We now feel comfortable to move forward." Phase 2 production will come initially from two development wells drilled for the test, with two water injectors to be added before first oil in June 1998. A third might follow, depending on further reservoir analysis.

For the floating production system, Conoco has commissioned a larger version of PGS' Ramform concept, hitherto employed purely for seismic vessels. The new double-hulled ship, under construction at Hyundai's Ulsan yard in South Korea, will measure 395 ft long by 175 ft wide. Other ship-shaped floaters in the North Sea are almost twice as long, at 700 ft.

The Ramform's delta shape, however, will allow it to support a 16,000-ton deckload comfortably. That compares with 4-5,000 tons for a semisubmersible, says PGS's Bjorn Bruheim, which may explain why his company was also shortlisted for a Petrobras drilling rig.

Banff's Ramform will be sited close to infrastructure from several other fields, and 8 km from the nearest tie-in to Amoco's CATS gas transmission trunkline. A new 6-in. diameter line from Banff will allow associated gas (the GOR is 650 mcf/bbl) to be exported at 20 mcf/d, with another 5 mcf/d retained for onboard fuel. In total, 39 bcf and 60MM bbl are currently thought recoverable, with further potential in other areas of the field.

Key item in the topsides will be a 3,500-ton process facility, allowing up to 60,000 b/d of oil to be produced and water handling at 90,000 b/d, alongside equipment for gas dehydration, compression and export, metering, utility systems, process/well control and shutdown systems. There is also storage capacity onboard for 120,000 b/d. However, this will not be used in the initial phase 2 production.

Instead, the plan is to climb quickly to peak production in 1999, offloading crude to a distant moored floating unit with 500,000 bbl storage capacity. A year later, perhaps, when production tails off to around 30,000 b/d, the FSU becomes unnecessary. Then the Ramform would assume storage duties as well, itself offloading to an ordinary shuttle tanker.

Here is where the economy factor kicks in. Other FPSOs are designed with high storage capacity which becomes virtual redundant as their fields deplete. The Ramform facilities, however, would be more fully utilized as Banff progresses through its anticipated seven-year lifespan, especially if more discoveries were brought onstream.

There are other cost savings compared with competing concepts. Bruheim claims that the Ramform requires less steel to accommodate conventional deck loads. The stability provided by the delta shape also limits the need for running the thrusters at full throttle, making it more energy-efficient than other vessels for heading control. For convenience, much of the equipment can be placed on the deck's rear, without sacrificing stability. As well as providing an easier to manage layout, it also leaves room for equipment upgrades arising from future subsea tiebacks.

PGS is confident of providing the vessel to Conoco and its partners by next June. DSND will manage subsea equipment installations. These include a five well-cluster manifold for the production and injection wells with flexible infield flowlines tied back to the FPSO via a dynamic riser system. Up to seven risers will be accommodated by the PGS-designed, fully weathervaning turret.

Operations split

Conoco is one of those operators that believes in devolving duties. As with its other UK sector FPSO project, MacCulloch, Banff's contractors will be responsible for production phase operations, leaving Conoco to manage drilling and reservoir performance. PGS, as lead contractor, is leasing the FPSO to the Banff Field partners, with Atlantic Power providing operational management of the vessel.PGS, which claims to deliver 80% of subsalt data from the Gulf of Mexico, is also applying 4D seismic to the Banff reservoir, with one of its vessels visiting the field periodically to monitor performance through the salt diapir. Another PGS vessel will be available to handle 3D seismic surveys over other prospects, with PGS in turn managing pre-stacked migration work.

MacMillan accepts that this first use of a turret-moored Ramform for production is a risk, although Bruheim points out that in seismic mode, the vessels are well proven in the rough waters west of the Shetlands. PGS is already pre-qualified for other FPSO contracts, he adds, "but the outcome depends, perhaps, on how Banff goes".

Copyright 1997 Oil & Gas Journal. All Rights Reserved.