Gopotes 1, a trailing suction hopper dredger, is one of the key vessels in HAM's fleet.

Fierce competition is expected among the Dutch dredging and rockdumping specialists this year, with the Interconnector and NorFra pipeline projects the key prizes to aim for in Europe. For the time being, however, the companies involved state that their order books are almost empty.

During 1995 work took place in deeper waters and rougher seabeds. Several remarkable projects were completed, such as the Troll Oil landfall.

Haltenpipe progress

Further work on the Haltenpipe project between the Heidrun Field and the Norwegian coast will take up most of 1996 for Van Oord ACZ and its Norwegian subsidiary, Jebsens ACZ. The 245 km, 16-inch gas pipeline is being installed by EMC in water depths down to 350 metres.

The pipeline crosses extremely rough bottom profiles, partly caused by scouring from icebergs during the Ice Age. But over the past two years Van Oord gained experience with rocky and highly irregular seabeds working on the dual 24-inch Europe Maghreb pipeline, installed by Saipem.

For the support of the pipeline segments in between the parts that would rest on the rock outcrops in the Straits of Gibraltar, Van Oord ACZ had to install pre-lay supports to prevent excessive free-spans and overstressing of the pipelines. To this end, rockdumping was performed at water depths down to 400 metres.

The local area, including soil data, was depicted in a 3D CAD model to determine the geometric modelling and optimise sleeper locations. Computer programs were also used to simulate the deviation of the flexible fall pipe during rockdumping caused by the tidal generated subsurface currents which in the Straits of Gibraltar flow in opposite directions.

Much closer to the Haltenbanken area, Van Oord ACZ prepared the installation of the Troll Oljeror pipeline between the Troll West oilfield and Statoil's own terminal at Mongstad. The 16-inch pipeline route crosses depressions in the Fensfjord down to 540 metres. On these highly sloped seabeds extra measures had to be taken to assure the pipeline's horizontal stability.

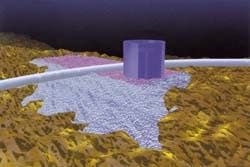

Using the fall pipe tower, Van Oord ACZ installed concrete support cylinders on the sea bottom, the skirt of which penetrated into the clayey soil. After installation, the cylinders were gravel filled.

The pipeline also was to enter a borehole leading to shore in 315 metres of water. To facilitate the pull-in, a 12 metre wide and 100 metre long rock embankment was constructed to serve as a ramp providing a smooth transition from the seabed into the borehole.

A comparable solution was found for Norske Shell's Troll Phase 1 pipeline which was to enter into vertical tunnels at 165 metres water depth near the Kollsnes gas terminal. Here, a gravel platform was constructed measuring 100 x 200 metres and 4 metres thick.

New approach to soil removal

Last year dredging and marine contractor HAM completed projects including the trenching, backfilling and landfall of several pipelines in Malaysia (Ppenang, Map Ta Phut), India and other Asian countries. Elsewhere, assignments included rockdumping and anti-scour work in Amoco Netherlands' P15/18 blocks.

Currently, the European offshore portfolio is more or less empty, according to Jos van Kuijk, deputy head of HAM's Offshore department. "Everybody in the industry is hoping for projects such as the NorFra and Interconnector pipelines. In the meantime, we focus on other areas and perform minor jobs such as stabilizing rigs, when a vessel is available."

Soon the company will bring into service the HAM 602 offshore supply vessel, equipped with a side stone dumping tower and a carrying capacity of 2,500 tons, twice as much as its sister vessel HAM 601.

The new vessel will be equipped for flow-dredging, a newly developed technique for soil removal operations. The flowdredger weighs 5 tonnes and generates a waterflow of up to 8 cu m/s by means of two counter-rotating impellers, thereby cleaning the soil in a very short timescale.

During the 14th World Dredging Congress in Amsterdam recently, Rene van Oostveen, manager of HAM's survey department, presented the Seabat multibeam sonar system mounted on the dredger itself. This enables the dredging or rockdumping vessel to perform its own bathymetric surveys without being dependent on a separate survey vessel. The system appears to be well suited for pre-sweeping pipeline routes and cleaning of subsea pipelines.

(Left) Once, installed the skirt of the cylinder penatrates the soil and can be filled up wit gravel.(Right) During the Troll Oljeror pipeline preparation exercise an ROV and the subsea stabilization cylinder are lowered from the fall tower to the seabed.

Besos outfall dredging

Two Dutch contractors, Smit Tak and Ballast Nedam Dredging, were involved in the Besos Long Sea Outfall off Barcelona. In a complex operation, Ballast Nedam had to dredge a 7 metre deep trench (30,000 cu m of sandy clay) beneath a high pressure gas pipeline located about a km offshore in 26 metres of water.

Because of its arterial role in the distribution of gas around Barcelona, the gas line could not be shut down. It was therefore supported on a 60 metre lattice steel support bridge. The owner of the gas pipeline, Gas Natural, was provided with a detailed explanation of the method and was involved in the development of work procedures.

This year, Ballast Nedam will bring into action its new trailing suction hopper dredger, the Amsterdam. With a hopper capacity of 18,000 cu m, this is one of the largest vessels of its kind worldwide. The vessel is being built by Merwede Shipyards.

The Amsterdam will be equipped with a dynamic positioning system and a forward scanning device which, in combination with a side-scan sonar, will enable three dimensional images to be taken of the dredge and dump locations.

Hainan line seabed softened

Belgian dredging firm Jan de Nul, with its Dutch subsidiary Dredging & Contracting Rotterdam, had to explore innovative ways of preparing the seabed for the new gas pipeline between Hainan Island off China and Hong Kong. Since the Hong Kong Authority did not permit the excavation of a trench in the Urmston Road area, the dredger decided to dilute the soil along the pipeline route to allow the pipeline to descend into the softened soil.

The trench with diluted material had a length of 71km and a maximum depth of 25 metres. Dilution took place by pumping the soil material into the hopper where it was mixed with water before being dumped into place again. After the pipeline was laid, the trench was backfilled with rock.

Another Dutch/Belgian company, Tideway, has been active on various assignments concerning the new gas pipeline between Scotland and Northern Ireland. Work included the landfalls on both sides of the 24-inch line which is operated by British Gas.

Copyright 1996 Offshore. All Rights Reserved.