Offshore staff

HOUSTON – SBM Offshore has revealed more details of its 2017 OTC Spotlight on New Technology award for the turret mooring system on the FPSOTurritella, which the company operates for Shell in the US Gulf of Mexico.

This is said to have established two new world records as:

1.) The world’s deepest floating oil and gas production system at 9,500 ft (2,900 m).

2.) The first use of steel lazy wave risers on a disconnectable turret mooring system (TMS).

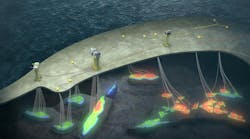

An FPSO in the GoM must be able to withstand severe meteorological conditions. The TMS, incorporating what is claimed to be the world’s largest disconnectable buoy, allows the FPSO to weathervane in normal conditions and to quickly disconnect from the buoy and safely sail away prior to the arrival of dangerous weather, such as a hurricane.

The reconnection capability also allows the FPSO to quickly resume production once the hurricane has passed the location.

The TMS for the FPSOTurritella project required for development and incorporation of four enabling technologies:

1.) Due to the ultra-deepwater and high-pressure steel risers, the disconnectable buoy had to be much larger than deployed on previous TMSs. The developed solution employs syntactic foam blocks rather than traditional steel plate for the buoy construction.

2.) To mate the giant buoy with the turret during reconnection, SBM developed a novel heave compensation system for pull-in operations.

3.) Connecting the buoy to the turret required structural connectors with capacities far above anything previously available.

4.) To adjust the tension in the mooring legs, SBM developed and qualified an in-line tensioning device to allow tension to be adjusted from a work boat. This avoided the need to tension the mooring legs from the buoy, and provided a means of compensating for any stretch in the polyester mooring legs during the TMS’ life - also allowing future systems to be installed in even deeper water.

The FPSOTurritella is an SBM Offshore Generation 2 design capable of handling 60,000 b/d of oil with 15 MMcf/d of gas treatment and export. Its Suezmax hull can store 800,000 bbl of crude oil.

SBM Offshore began work on the concept and design of the TMS with Shell in 2011. EPCI work started in mid-2013 when the contractor was awarded the supply and lease contracts for the FPSO.

05/03/2017