North Sea Troll gas dehydration package to minimize TEG losses

Offshore staff

HOUSTON – ProSep will supply a ProDry processing system to Aker Solutions for Statoil’s Troll B ZMP project in the Norwegian North Sea.

Greg Hallahan, ProSep’s director of product development, said: “The ProDry technology has demonstrated the ability to dehydrate natural gas with nearly 100% approach to equilibrium.

“This enhanced performance, as compared to standard injection quills, allows significant cost savings via replacement of standard countercurrent towers, eliminating the large vessels and internals.

“Additional savings in operating expenses can be realized by minimizing TEG [triethylene glycol] losses and demonstrating resilience to common TEG tower issues, such as TEG foaming and carryover.”

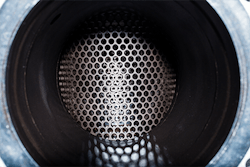

The system to be deployed on theTroll B platform will feature ProSep’s ECLIPSE mixer for TEG injection. Due to the system’s claimed high mixing efficiency, Statoil will replace a standard countercurrent TEG tower with an in-line, co-current mixer and separator/knock-out drum.

In this way the required TEG flow compared to a conventional tower will be reduced, allowing use of spare capacity in the existing TEG regeneration packages.

Jacek Kacperski, ProSep sales manager for Europe, added: “This project represents the first time the ECLIPSE mixer has been installed for gas dehydration with TEG or MEG, the ProDry application, and brings to conclusion a year-long R&D and business development effort to reach commercialization.

“ProSep feels that this application is the first step toward proving the mixers capability as part of an in-line co-current system, which has future applications for subsea developments.”

02/17/2017