Offshore staff

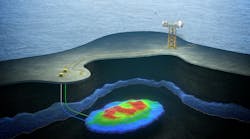

CRAILSHEIM, Germany/OSLO, Norway – Voith and Funglesangs Subsea (FSubsea) have agreed to co-develop hydrodynamic variable-speed drives for subsea pump applications.

Voith says that with its torque converter integrated in the pump on the seafloor, variable frequency drives (VFDs) on topsides will no longer be needed for speed control.

Current subsea boosting systems depend on a topsides VFD with several hundred tons of weight and extensive module size, the partners point out, which can be difficult to integrate on a platform or FPSO.

In contrast, the Voith/FSubsea solution involves integration of a torque converter (a mechanical variable-speed device) in the pump based on the seafloor. This, combined with Hydromag technology, provides a hermetic pressure barrier between the process and the motor cooling fluid, rendering a barrier fluid system and electrical control units unnecessary.

No topsides facilities, seafloor based auxiliary pumps, hydraulic fluid connections, and signalling cables should therefore be needed forsubsea boosting, potentially lowering capex and opex costs by up to 70%, and at the same time simplifying the entire set-up.

As the system is independent of any umbilicals besides electric power, it could open the way toward longer step-outs far beyond current capabilities, the partners add.

For increased oil recovery in brownfield and greenfield operations, all that is required is an additional motor starter on existing platforms and FPSOs to enable them to managesubsea boosting.

05/31/2016

Share your news withOffshore at [email protected]