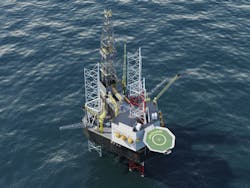

Cameron unveils Letourneau Jaguar class self-elevating drilling unit

Offshore staff

HOUSTON – Cameron has introduced a new drilling unit to the market, the Letourneau Jaguar class self-elevating mobile offshore drilling unit. Utilizing the Letourneau 1000-Kip elevating unit and the Letourneau storm LOK leg fixation system, the Jaguar is capable of operating in water depths up to 400 ft (122 m) in harsh conditions or 500 ft (152 m) in moderate waters.

The rig also has the capacity to drill ultra-high-pressure/high-temperatures wells to 40,000 ft (12,192 m) with a hook load of 2.5 million pounds and setback capacity of 1,700 kips in quads, filling the market gap between the typical premium and ultra-large jackups,Cameron said.

Unique to Letourneau rig designs, the Jaguar only requires a leg fixation system in severe storm conditions. This design feature allows for approximately a half-day savings each time a rig is moved. Another unique feature of the Jaguar is the design of its spud can and leg well, which allows for pulling individual legs above the waterline; permitting classification society Special Periodic Survey inspection without dry docking, potentially saving weeks of downtime and hundreds of thousands of dollars.

Other design features include:

- Cantilever with 1,542 MT (3,400 kip) maximum combined drilling load capacity, longitudinal reach of 24.4 m (80 ft) or greater, and transverse skidding movement of ±7.6 m (25 ft) of the rig centerline.

- Drilling variable deck load including cantilever loads of more than 6,800 MT (15,000 kips) in 36 m/s (70 knot) winds. Severe storm variable deck load of more than 5,000 MT (11,000 kips) in 51 m/s (100 knot) winds.

- Storage to well handling of two 25,000 psi BOP stacks.

- Includes 11 active/reserve mud pits and two slugging pits, with a 7,770-bbl combined capacity. Expanded pit capacity can be easily integrated during construction or may be retrofitted post-delivery.

- Mud systems large capacity and dedicated piping accommodates simultaneous use of oil, saltwater, and fresh water-based muds without cross contamination.

- Automated tubular handling from pipe rack to downhole, including independent stand making.

04/24/2015