Offshore staff

ABERDEEN, UK– SubCool has developed an active cooling solution and the processes to treat hydrocarbon fluids subsea.

Despite advances in subsea technology, the oil and gas industry continues to rely on “end-of-pipe” flow assurance solutions, instead of properly processing the fluids prior to transportation. These “end of pipe” additive technologies include chemical injection, insulation, and heating. The company says it is now possible to produce “Sales Gas Subsea.”

In general gas has always been processed by cooling to remove water and condense liquids, for both surface facilities and onshore. Cooling is readily achievable subsea because the coldest water temperatures and the best heat sink are near the seabed.

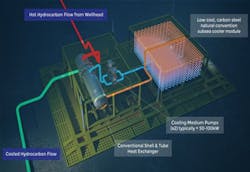

The SubCool robust active cooling technology uses a traditional shell and tube heat exchanger subsea to cool the gas to the right temperature. A self-contained subsea cooling medium system allows exact temperature control, while ensuring a reliability and robustness not possible with an open seawater system.

The company says the system permits removal of 80-90% of the condensed water, all the produced water and associated salts, and much of the condensate liquids. According to the company, the system simplifies transportation from deepwater and long distance tiebacks.

SubCool is exhibiting at booth D28.

10/14/2014