Reaming system solves obstruction in North Sea well

Offshore staff

ABERDEEN, UK – Deep Casing Tools has completed a 21-hour reaming run on its first operation in the Norwegian North Sea.

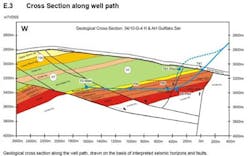

Two previous attempts to run a 7-in. liner in aGullfaks field satellite well using conventional technology had failed, and the liner was hung up hundreds of meters from total depth.

The problem was due to borehole instability and severe washout in the weak shales, coals, and paleosols of the area. However, the Gullfaks team managed to drill the side track using low energy drilling principles and ran the liner withDeep Casing Tools’ Turbocaser Express as a contingency against wellbore obstructions. This high-speed drillable reaming system allows drillers to land casings and intermediate liners at target depth the first time.

For operator Statoil there were two benefits, according to Deep Casing Tools. The Turbocaser Express would increase the chance of getting the liner to total depth, and if hole conditions proved too severe, its full-bore rapid drill through capability would allow the remaining reservoir to be accessed.

The 7-in. liner ran and, as predicted, stood up with 10 metric tons (11 tons) at 1,260 m (4,134 ft) from total depth, where the liner could not be rotated or run deeper. Circulation was established and the tool was used to clear the obstruction.

The next obstruction was at 4,378 m (14,363 ft) where the tool was again used to ream, and this was repeated most of the way to total depth. Total reaming time was 21 hours, at an average rate of 60 m/hr (197 ft/hr).

1/8/2013