Offshore staff

STAVANGER, Norway –Statoil has conducted a subsea pipeline hot tap operation in a record manner at Ǻsgard in the North Sea. For the first time ever, remote-controlled equipment and a subsea welding robot have installed a new tie-in on a live gas line with no other preparation.

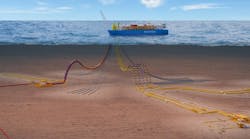

The tie-in was welded onto the Ǻsgard B production flowline in 265 m (879 ft) of water using Technip’sScandi Arctic vessel.

The project consisted of a robot welding a T-piece on to the pipe while gas continued to flow. Then, a remote-controlled drilling machine put holes in the producing pipeline with no effect on pressure and production.

The method was developed by Statoil from work begun in 1999.

When the compressor module and manifold for Åsgard subsea compression are installed next year on the seafloor, Statoil plans to connect the pipeline from these structures to the hot-tap tie-in point.

Åsgard subsea compression is due to start up in 2015, and is designed to improve recovery from the Mikkel and Midgard reservoirs by about 280 MMboe.

Remote-controlled hot tap has been done on Tampen Link on the Statfjord field in the North Sea and on the Ormen Lange field in the Norwegian Sea, but then the T-piece was installed pipeline in advance of the tie-in.

9/13/2012