Offshore staff

LONDON – The SureFlex report, published in 2010 by Oil & Gas UK is being used to encourage the international oil and gas industry to make better use of flexible pipe in subsea and floating oil and gas developments. The report incorporates data and experience from the use of flexible pipe drawn for the first time from all major flexible pipe operators, manufacturers and independent specialists worldwide.

Paul Dymond, Oil & Gas UK’s operations director, said: “The SureFlex report has been compiled by Wood Group Kenny to provide updated guidance on flexible pipe integrity assurance and state-of-the-art analysis of flexible pipe integrity technology. These comprehensive best practice guidelines will help the industry in oil and gas provinces around the world, to harness the wide-ranging opportunities presented by the growth of subsea developments.”

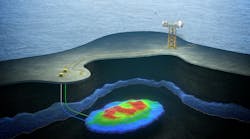

“Subsea developments are on the increase because operators are addressing the challenge of extracting hydrocarbons from fields that are remotely located, have reduced reservoir sizes or are being developed in deeper water.

“Subsea technology, including flexible pipe used to transport hydrocarbons above the seabed, allows cost effective extraction in increasingly challenging environments maximizing the use of existing infrastructures and avoiding the need to build new fixed production platforms at each offshore development site. The SureFlex report, commissioned by Oil & Gas UK, aims to provide best practice guidelines to the international oil and gas community and incorporates data drawn from more than 25 years of operational experience in the use of flexible pipe.”

Patrick O’Brien, group director of strategic business and marketing, Wood Group Kenny, said: “The technology is also a key element of floating production field developments. Flexible pipe is used extensively in the oil and gas industry as it is the most viable technical and commercial solution for a variety of typical offshore pipeline systems including dynamic risers connected to floating production vessels and as infield flowlines for subsea developments.

“Recent industry reports suggest that two thirds of all new fields in the UK are likely to be developed as subsea tiebacks, which is testament to the benefits of subsea technology. The advantages of the technology are increasingly being recognized by operators in the Gulf of Mexico and other international offshore regions. This report captures important operational experience to enhance the future design and usage of flexible pipe worldwide. Key findings from the work are being presented at the OTC conference in Houston this week.”

05/04/2011