Judy Maksoud

International Editor

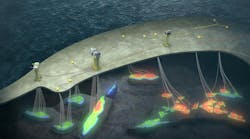

ST. JOHN'S, Newfoundland and Labrador -- Sustaining production in trying weather conditions is the objective of a number of new technologies. Among them, is the submerged turret loading (STL) system developed by Advanced Production & Loading Inc. of Norway.

Jens Kaalstad, president of APL, talked about the application of his company's technologies and a number the company's successes at the Newfoundland Ocean Industries Association (NOIA) annual meeting on June 19.

Kaalstad told NOIA conference participants that the disconnectable turret has worked in the North Sea, in typhoons in Southeast Asia, in hurricanes in the Gulf of Mexico, and in nor'easters offshore New England. During the 2005 hurricane season in the GoM, an installation using APL's equipment remained operational through both Hurricane Katrina and Hurricane Rita.

The STL allows production in extreme conditions, Kaalstad said. "STL installations are the last to shut down and the first to restart production."

The most recent of the company's installations was carried out on June 7. The FPSOYùum K'ak' Náab, which will produce the Ku-Maloob-Zaap (KMZ) field in the Bay of Campeche, was towed into position for connection to the preinstalled STP system. Retrieval and pull-in of the buoy was carried out, and the vessel was securely moored in an operation that took less than 5 hours.

The vessel, which has a 2.4 MMbbl storage capacity and the ability to process 600,000 b/d is designed for 100-yr hurricane conditions, Kaalstad said.

APL's technology also has been applied on the Heidrun field in the North Sea, where the installation has achieve 99.99% uptime offloading since the equipment was installed in 1994, Kaalstad said. The technology is also being applied in offshore LNG terminals.

6/19/2007